tkrrox

Plastic

- Joined

- Sep 2, 2008

- Location

- castaic california

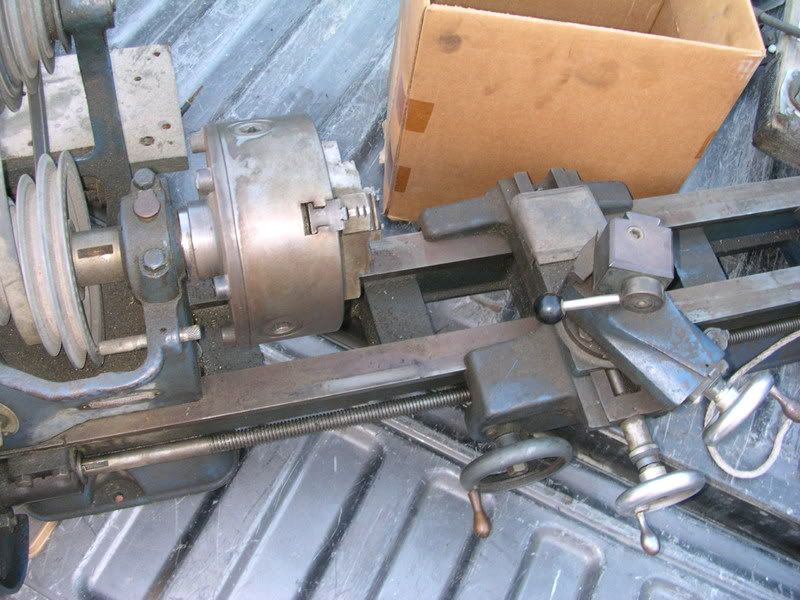

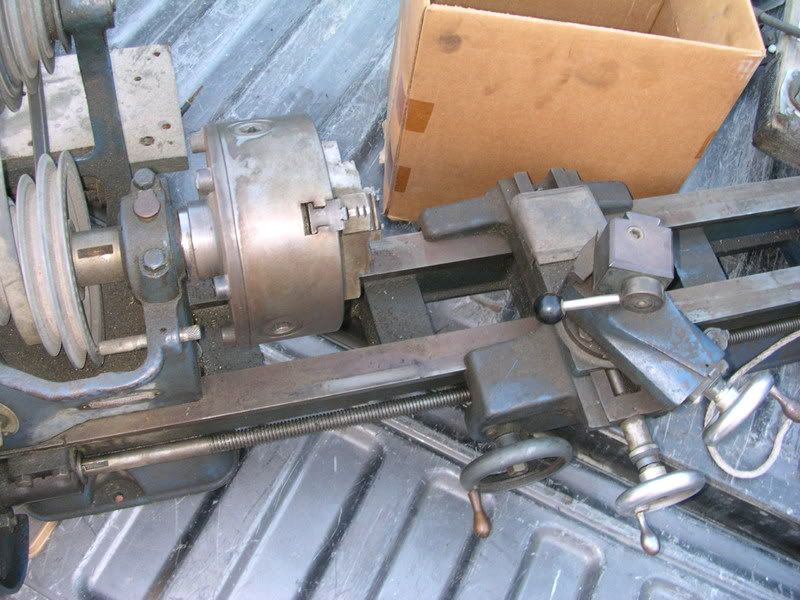

i just picked this up...and i will admit i have no knowledge of lathes...i did do some research and found that altas built these...

http://www.lathes.co.uk/craftsman/index.html

a lot of what i've learned is by the sight above...

i am curious on if the altas parts are interchangeable and if anyone has insight if i just wasted my money or it was a decent purchase...i was given 2 motors with it and i haven't wired it yet to see it work...the bearings feel good, but the sled did have play, which i'm thinking/hoping i can adjust out....

any insight will be helpful...the pics on the sight above are close to the model but have differences...

thanks

taryn kelley

http://www.lathes.co.uk/craftsman/index.html

a lot of what i've learned is by the sight above...

i am curious on if the altas parts are interchangeable and if anyone has insight if i just wasted my money or it was a decent purchase...i was given 2 motors with it and i haven't wired it yet to see it work...the bearings feel good, but the sled did have play, which i'm thinking/hoping i can adjust out....

any insight will be helpful...the pics on the sight above are close to the model but have differences...

thanks

taryn kelley

The crossfeed handwheel is broke, and the crossfeed screw bent; the tailstock wheel is broke; the leadscrew support on the tailstock-end is broke; and the rear leg of the headstock end shattered, and all that is left is about 1" of casting holding it up....

The crossfeed handwheel is broke, and the crossfeed screw bent; the tailstock wheel is broke; the leadscrew support on the tailstock-end is broke; and the rear leg of the headstock end shattered, and all that is left is about 1" of casting holding it up....