Dreadnought_T5

Plastic

- Joined

- Nov 6, 2022

Hello Everyone,

I inherited my father's Gearhead a few years ago, serial number 29925. Looks to be an 18 speed with BB spindle bearings. I've heard the bearings are quite pricey to replace, not quite sure of the condition or longevity of the ball vs. taper bearings. They may be fine, but haven't checked the runout of them yet (the lathe has been in storage up to this point).

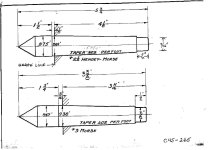

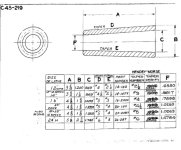

For the life of me, I cannot find documentation on the tailstock taper. It looks to be MT3, but can anyone confirm?

Johnoder, Thank you for providing the 1940 Op Manual in other threads. It's been a great resource.

Hendeyman, I would be in your debt if you had any information on the history of this machine. My grandfather procured it from somewhere after the war. He started his machine shop sometime in 1946, then later my father ran it. Fate would take me in a slightly different direction, but definitely feel a connection to this machine (and his Series I Bridgeport). Just recently acquired some space to put them both back into service, and hopefully teach my children a few things on them as the years go on.

I've been watching several overhaul / reconditioning threads here, and I'm anxious to start down a similar path with mine. I'll post pictures once I have my shop space set up.

Thank you, and take care,

Dreadnought

I inherited my father's Gearhead a few years ago, serial number 29925. Looks to be an 18 speed with BB spindle bearings. I've heard the bearings are quite pricey to replace, not quite sure of the condition or longevity of the ball vs. taper bearings. They may be fine, but haven't checked the runout of them yet (the lathe has been in storage up to this point).

For the life of me, I cannot find documentation on the tailstock taper. It looks to be MT3, but can anyone confirm?

Johnoder, Thank you for providing the 1940 Op Manual in other threads. It's been a great resource.

Hendeyman, I would be in your debt if you had any information on the history of this machine. My grandfather procured it from somewhere after the war. He started his machine shop sometime in 1946, then later my father ran it. Fate would take me in a slightly different direction, but definitely feel a connection to this machine (and his Series I Bridgeport). Just recently acquired some space to put them both back into service, and hopefully teach my children a few things on them as the years go on.

I've been watching several overhaul / reconditioning threads here, and I'm anxious to start down a similar path with mine. I'll post pictures once I have my shop space set up.

Thank you, and take care,

Dreadnought