Spookydad

Plastic

- Joined

- Dec 15, 2011

- Location

- Houston, Texas

I now have a Jiangdong HX30 milling machine and have no information about it. A google search doesn't seem to find any information but I was told that these machines were imported and resold under different badges but I don't know the names.

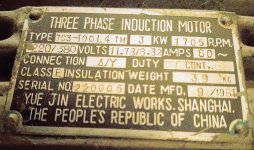

It is a 240v 3 phase machine using a CAT40 tool holder system. However the only holder I got with it doesn't have a pull stud and the head seems to use a traditional Bridgeport style drawbar through the top. It is a large machine and tightening the drawbar would require a ladder. There is no drawbar so I don't know if this is the correct method.

It starts up but there is a lot of flickering of the lights and arcing. I'm using an American Rotary phase converter with a separate idler motor rather than a VFD.

I have owned a genuine Bridgeport mill, LeBlond lathe, Clausing Surface grinder in the past, but had to leave them behind due to a cross country move.

Any help would be appreciated.

It is a 240v 3 phase machine using a CAT40 tool holder system. However the only holder I got with it doesn't have a pull stud and the head seems to use a traditional Bridgeport style drawbar through the top. It is a large machine and tightening the drawbar would require a ladder. There is no drawbar so I don't know if this is the correct method.

It starts up but there is a lot of flickering of the lights and arcing. I'm using an American Rotary phase converter with a separate idler motor rather than a VFD.

I have owned a genuine Bridgeport mill, LeBlond lathe, Clausing Surface grinder in the past, but had to leave them behind due to a cross country move.

Any help would be appreciated.