I have been working away at restoring a SB 10L lathe, SN 146767 with marks W.E.F. and L.Q.R. There is also a lightly stamped circle with some sort of symbol in it. I removed the under cabinet motor mount assembly by unbolting it and lifting the cabinet off so that I can clean and paint the cabinet. No obvious problems with the motor mount other than the thick oily crud. Spent a couple of hours or so with various brushes and gasoline to get the worst of it off. Everything works smoothly but I may disassemble it to lubricate the various pivot points and shafts because there are no holes or oil cups to lubricate the shafts

The motor is clearly not original, my question is how about the motor pulley? I suspect this was a 12 speed lathe so a 2 step pulley? The parts list I have says contact south bend with the serial number to get the correct pulley. Anyone have any idea what it should be?

I guess I could do some measurements of pulley sizes and RPM to make an educated guess but I suspect there will be some trial and error to get the correct belt tension on both sizes. I am not sure what the maximum RPM should be for the old segmented iron headstock bearings.

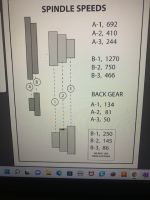

Was there ever a table that showed which belt and back gear locations provide what RPM?

The motor is clearly not original, my question is how about the motor pulley? I suspect this was a 12 speed lathe so a 2 step pulley? The parts list I have says contact south bend with the serial number to get the correct pulley. Anyone have any idea what it should be?

I guess I could do some measurements of pulley sizes and RPM to make an educated guess but I suspect there will be some trial and error to get the correct belt tension on both sizes. I am not sure what the maximum RPM should be for the old segmented iron headstock bearings.

Was there ever a table that showed which belt and back gear locations provide what RPM?