G&L4nahalf

Cast Iron

- Joined

- Jul 27, 2014

- Location

- Temporarily Florida

PART 1 OF 2 PARTS A summary of the evolvement of the Engine-Lathe in the USA. part 1 of 2

The impetus and background for the start of the modern Engine-Lathe development in the USA. Power and need.

We should be aware, that prior to 1775, the USA colonies were forced by law, to buy textiles and finished clothing from England. After the Revolutionary war of 1775 to 1781, that was no longer necessary, and textile technology had advanced to the point that water-power was the only viable option for powering the mills in the USA. Some of those plants were operating thousands of spinning spindles. There were really only ~ a half-dozen sites in New England suitable for textile water-wheel power. The two main ones were the Blackstone river at Pawtucket RI, and the Vermont-New Hampshire river at Windsor Vt.

The water-wheels were constructed in situ, that is : after the wheel-pit was constructed, the axle was fitted, installed, balanced, etc., in the pit. Then, the frame for the wheel was built around it in the pit, followed by the bucket construction onto the frame. The final operation was affixing leather flaps over holes in the buckets for expediting water release on the upcycle. I had originally thought that some how the finished wheel was lowered into the pit. Not so.. Every thing from the axle on, was done right in the pit located in the basements of those textile mills. Normally, the mills had 3 or 4 floors, constructed in a narrow long rectangular configuration, utilizing sunlight and line-shafting for the machinery. 6 - 12 hr days were the normal work week, and night-work was normally not done, as those plants were proven to be extreme fire-hazards. The shop facilities for repair and maintenance were typically located in the basement next to the water-wheel main shaft. The wheels turned ~ 5 rpm, weighed in the range of 15-20,000 lbs, and lasted just 7 years even with the best wood and maintenance. Then, it had to be a new rebuild. The 18' dia @ Windsor, is believed to have put out ~50 hp; with ~1/2 of that useable on the machinery itself, drawn from the line-shafting by flat leather belts. The wheel-speed needed to be governed for the textile-thread machinery, and it was automatic by lowering and raising the final sluice gate for the water flow to the wheel. I do not know the mechanism designs. There were complaints about response time lag for the varying need for water volume and consequent line-shaft speed.

This then, would be the situation for power for the machine-tool industry for about the next 75 years. Steam-power was only dominant for about 25 years, and as soon as possible after 1900, everyone converted to electric power as they were able.

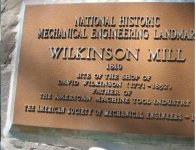

The Wilkinson family of Rhode Island, was a very talented mechanical-blacksmith-machinist family following the Revolutionary War. Oziel the father, with his sons, built an advanced steel-mill that supposedly put out the finest "blister steel" in America. He did work for the Navy, primarily anchors. Also metal work for the textile mills, and in addition - a major achievement for the time; nail making - at the peak about 4,000 lbs a day. These included round nails in the 20 to 50P range; for what use I do not know. Another son made the finest wire at the time; and used a horse to draw it (through dies ?). That son also made sewing needles ($ 1 apiece).

The Wilkinson family is the real father of the industrial revolution.. Largely unrecognized for their accomplishments at the time, they gave an immense jump start to the United States economy; which was without input from England - totally home grown. By the 1870s the USA industrial output overtook England's, and the gap has continued to widen to this day.

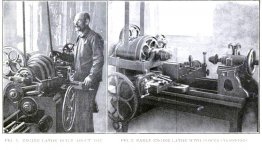

As many are aware, before young David Wilkinson invented his thread cutting lathe (prior to 1794), ALL lathes before his invention, were primarily wood with a small amount of metal components. ALL turning - wood and metal, was by human muscle-power, using a stationary rest, and in the case of metal - a long lever bar with a metal cutting tip. Descriptive cartoon below.

Pre 1800 on the left of course.

David Wilkinson's threading lathe below, designed to produce press screws turned by a hand-wheel. A few years later, he modified it into a general-purpose lathe that was widely adopted.

With direct drive from the water-wheel, he had access to a good 20 - 30 hp on the spindle work-driver. With a 20' bed, and the capability of turning a bar of steel at least 12' long and 6-8" dia, he had a real industrial class engine-lathe.

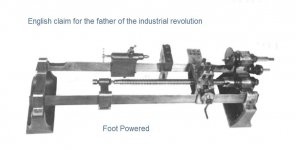

Contrast this fact with the English claim for Maudslay being the inventor of the Engine-Lathe. D W beat Maudslay by a few years. Maudslay's lathe had no bed, was foot-treadle powered ( 1/10hp ) capability of turning about 1" dia ~20" long, with a maximum cut of only 2 or 3 thousandths deep. His machine was small enough to carry with one hand. Would anyone now or then, order ANYTHING for their shop work that had a 1/10hp motor ?

I have at least 5 images of very old USA Engine-Lathes with a uniquely American and almost identical design. Plus there are known to be probably a dozen other Engine-Lathes in the USA with identical features to my images. Since we know from an Act of Congress that David Wilkinson's design was used on at least 200 Engine-Lathes working in the USA Armories by 1848, not counting Engine-Lathes in private use, it would seem to be reasonable to conclude that these very old Engine-Lathes with an uniquely American identical design, are survivors of the original David Wilkinson design. To think that they are possibly the result of some other unknown inventor, who was inadvertently never mentioned in the USA historical records; is imo, unreasonable.

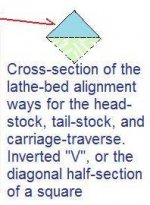

Therefore, the evidence seems to show that the David Wilkinson design had 4 sharp-angled rails [gage] for the way-guides; with a chain driven feed for the cutting mechanism carriage, and with a RACK AND PINION supplement to the chain drive.. .

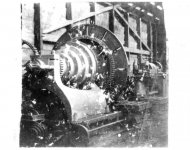

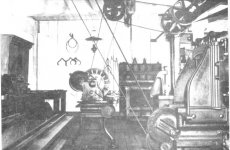

Image of a very old Engine-Lathe from the Wilkinson Mill museum in Pawtucket, Rhode Island.

Part one of two, part 2 to follow in the next post.

The impetus and background for the start of the modern Engine-Lathe development in the USA. Power and need.

We should be aware, that prior to 1775, the USA colonies were forced by law, to buy textiles and finished clothing from England. After the Revolutionary war of 1775 to 1781, that was no longer necessary, and textile technology had advanced to the point that water-power was the only viable option for powering the mills in the USA. Some of those plants were operating thousands of spinning spindles. There were really only ~ a half-dozen sites in New England suitable for textile water-wheel power. The two main ones were the Blackstone river at Pawtucket RI, and the Vermont-New Hampshire river at Windsor Vt.

The water-wheels were constructed in situ, that is : after the wheel-pit was constructed, the axle was fitted, installed, balanced, etc., in the pit. Then, the frame for the wheel was built around it in the pit, followed by the bucket construction onto the frame. The final operation was affixing leather flaps over holes in the buckets for expediting water release on the upcycle. I had originally thought that some how the finished wheel was lowered into the pit. Not so.. Every thing from the axle on, was done right in the pit located in the basements of those textile mills. Normally, the mills had 3 or 4 floors, constructed in a narrow long rectangular configuration, utilizing sunlight and line-shafting for the machinery. 6 - 12 hr days were the normal work week, and night-work was normally not done, as those plants were proven to be extreme fire-hazards. The shop facilities for repair and maintenance were typically located in the basement next to the water-wheel main shaft. The wheels turned ~ 5 rpm, weighed in the range of 15-20,000 lbs, and lasted just 7 years even with the best wood and maintenance. Then, it had to be a new rebuild. The 18' dia @ Windsor, is believed to have put out ~50 hp; with ~1/2 of that useable on the machinery itself, drawn from the line-shafting by flat leather belts. The wheel-speed needed to be governed for the textile-thread machinery, and it was automatic by lowering and raising the final sluice gate for the water flow to the wheel. I do not know the mechanism designs. There were complaints about response time lag for the varying need for water volume and consequent line-shaft speed.

This then, would be the situation for power for the machine-tool industry for about the next 75 years. Steam-power was only dominant for about 25 years, and as soon as possible after 1900, everyone converted to electric power as they were able.

The Wilkinson family of Rhode Island, was a very talented mechanical-blacksmith-machinist family following the Revolutionary War. Oziel the father, with his sons, built an advanced steel-mill that supposedly put out the finest "blister steel" in America. He did work for the Navy, primarily anchors. Also metal work for the textile mills, and in addition - a major achievement for the time; nail making - at the peak about 4,000 lbs a day. These included round nails in the 20 to 50P range; for what use I do not know. Another son made the finest wire at the time; and used a horse to draw it (through dies ?). That son also made sewing needles ($ 1 apiece).

The Wilkinson family is the real father of the industrial revolution.. Largely unrecognized for their accomplishments at the time, they gave an immense jump start to the United States economy; which was without input from England - totally home grown. By the 1870s the USA industrial output overtook England's, and the gap has continued to widen to this day.

As many are aware, before young David Wilkinson invented his thread cutting lathe (prior to 1794), ALL lathes before his invention, were primarily wood with a small amount of metal components. ALL turning - wood and metal, was by human muscle-power, using a stationary rest, and in the case of metal - a long lever bar with a metal cutting tip. Descriptive cartoon below.

Pre 1800 on the left of course.

David Wilkinson's threading lathe below, designed to produce press screws turned by a hand-wheel. A few years later, he modified it into a general-purpose lathe that was widely adopted.

With direct drive from the water-wheel, he had access to a good 20 - 30 hp on the spindle work-driver. With a 20' bed, and the capability of turning a bar of steel at least 12' long and 6-8" dia, he had a real industrial class engine-lathe.

Contrast this fact with the English claim for Maudslay being the inventor of the Engine-Lathe. D W beat Maudslay by a few years. Maudslay's lathe had no bed, was foot-treadle powered ( 1/10hp ) capability of turning about 1" dia ~20" long, with a maximum cut of only 2 or 3 thousandths deep. His machine was small enough to carry with one hand. Would anyone now or then, order ANYTHING for their shop work that had a 1/10hp motor ?

I have at least 5 images of very old USA Engine-Lathes with a uniquely American and almost identical design. Plus there are known to be probably a dozen other Engine-Lathes in the USA with identical features to my images. Since we know from an Act of Congress that David Wilkinson's design was used on at least 200 Engine-Lathes working in the USA Armories by 1848, not counting Engine-Lathes in private use, it would seem to be reasonable to conclude that these very old Engine-Lathes with an uniquely American identical design, are survivors of the original David Wilkinson design. To think that they are possibly the result of some other unknown inventor, who was inadvertently never mentioned in the USA historical records; is imo, unreasonable.

Therefore, the evidence seems to show that the David Wilkinson design had 4 sharp-angled rails [gage] for the way-guides; with a chain driven feed for the cutting mechanism carriage, and with a RACK AND PINION supplement to the chain drive.. .

Image of a very old Engine-Lathe from the Wilkinson Mill museum in Pawtucket, Rhode Island.

Part one of two, part 2 to follow in the next post.