cncFireman

Hot Rolled

- Joined

- Jun 19, 2013

- Location

- Farmington Missouri

That is very interesting the idea of link chain used for a screw lathe. It seems as if makers had a few different ways to power feed a slide in the early days.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

At MIT there is an exceedingly brilliant proffesor of linguistics called Noam Chomsky, born and bred in America, and writer of over 100 books. If you want to know why American recorded history is, shall we say "unreliable" I would suggest you all read some of them, especially "For reasons of state" You would then realise why the American establishment has been editing and rewriting its history for generations.

Yes that was obvious to us too. The mystery is what is the rack doing there ? Without checking, it seems there were racks on at least some of the other Wilkinson lathes too.

The problem then becomes how does the hand-wheel pinion engage and/or disengage the chain and/or rack ? I don't think the system had the hand-wheel turning all the time; there had to be some reason why the Wilkinson wood-bed lathe had leather strips fastened on the OD, obviously for gripping. Did someone put them on later when they converted the lathe to a wood-lathe ? I don't think so. But maybe...

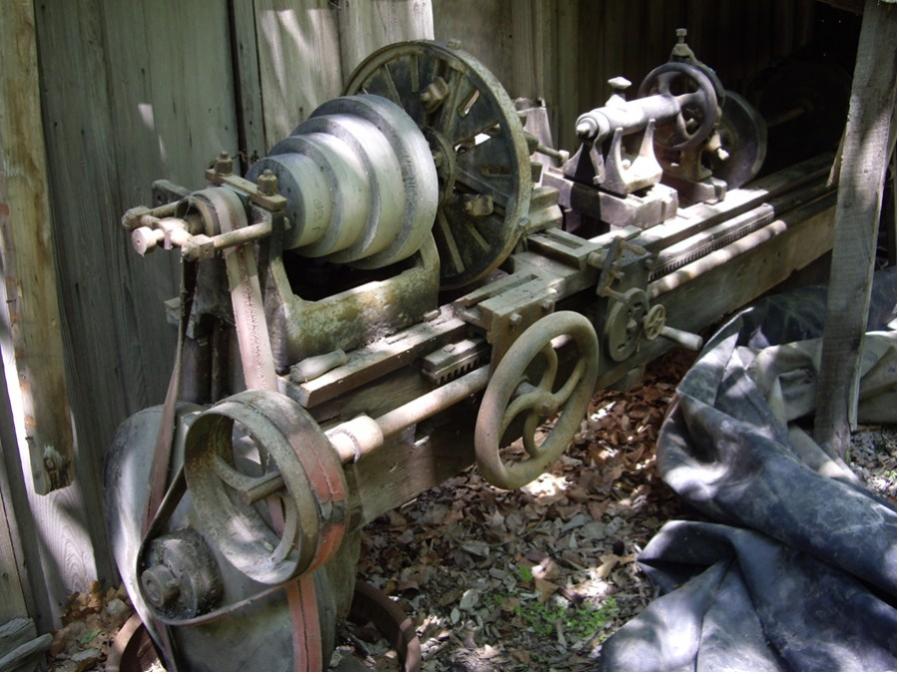

Possibly someone might have more info on the chain drive on some of the other of these machines.. Especially the "corn-field" lathe brought up by cncFireman.

George

G

My comments have not been personal.

Nor, I imagine, are the comments made by regular contributors to this forum, who have forgotten more than I know about the early history of machine tools.

Contributors who I invite to shoot me down in flames for any incorrect assumptions made below.

The contributors here are not motivated by hopes of personal gain.

They are not motivated, as many contributions to PM are, by a need to get machines running ASAP to keep a roof over their head and food on the table.

The discovery of the Antikythera mechanism destroyed many assumptions about technological advances C0BC.

There may be some artifacts in the tombs of Chinese Emperors from a similar historical period which will similarly revolutionise historical thinking about the origins of mechanical engineering.

Nobody knows how much evidence remains of mechanical engineering history in Europe and North America since 1707. 1707 being the date which my searches indicate was when the first Newcomen engine was installed.

What is, I hope, agreed, is that we examine the evidence first; evidence however fragmentary, incomplete, and unsatisfactory. Only thereafter do we create explanations, called hypotheses in the so-called "exact sciences". Hypotheses which will probably be forever provisional.

We do not start with the conclusion and then select the "evidence" to conform thereto.

Suggestion G, tabulate your findings (Excel spreadsheet or similar). This will highlight similarities/differences, and possibly patterns of machine tool development, which will not be as evident using your text based contributions hitherto.

If you can demonstrate, or at least posit, some new explanations, which accord with the currently available facts, I will congratulate you, here. I would expect most contributors would do the same.

But this cannot be on your terms, you must follow the procedure noted above, not because I say so, but because that is the only way you will get credibility.

Best wishes

Rich

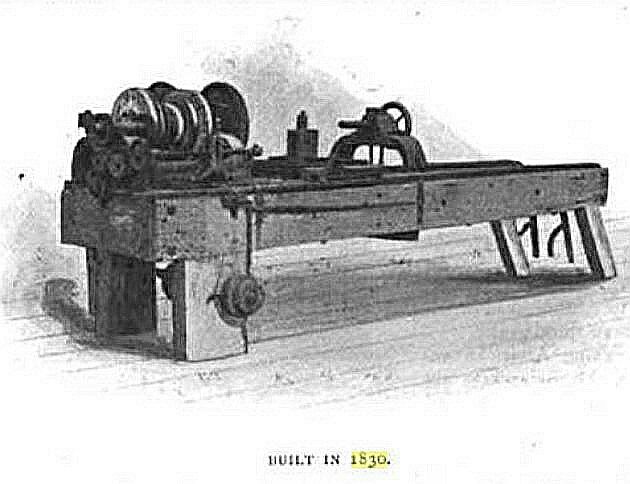

At full travel the rack would protrude from the end of the bed like the twin off the Moffet Mills lathe in possession of one of the members here like shown below. Another reason why some builders may have gone the way of using a chain for feed to not have a rack sliding in and out of the end of the bed. Some of the makers may have opted for a chain also over a leadscrew as they may have not had the resource to turn a screw accurately enough for use. Just a thought I doubt we will ever fully understand the choices they made.

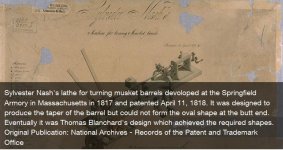

Does any one have a picture of the first Putnam lathe as seen in the picture below? I thought I had read that the Fitchburg Historical Society has the lathe?

I have been in machine-shops hardly without interruption for now 73 years. I have been running engine-lathes, for 62 years,

For me, the key is in your Getty image, and this as yet unexplained mysterious rack moving in an out the lathe.

It has been posted on PM before in some of the older threads.I does look like a direct drive pinion. The older wood bed early lathe I have recently taken in is missing its pinion and I am planning to build a direct drive wrong way pinion to try it out for simplicity.

I'm still not sure where you're going with this George? There's nothing revolutionary about the use of a rack drive .I think a crucial detail is whether the rack teeth are up or down on the other machines.

That's within about 10 ! years of David Wilkinson's invention of the general purpose engine-lathe.

Well I tried, and failed, twice.

I should have known better, the first time.

I should not have tried the second time.

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.