Hello Russ,

I think I can help with this topic.

When using adaptive toolpaths the max cutting feedrate is used to define the " link back move" (non-cutting reposition move )

You can adjust this number up or down for what makes sense for your machine / shop environment.

BobCAD offers multiple feedrate mapping options for 2D, 3D and 4 and 5 Axis. In this example ( 2D adaptive pocket ) you can choose from 3 feedrate options, standard, ( up and down feedrate values ) , Volume based - feedrate ramps up and down based on the volume of material the tool is engaged with. Or Radial chip thinning, which is popular to use with adaptive, ramping up and down feedrates to maintain a chip size.

Learn more about adaptive machining here -

https://bobcad.com/in-depth-guide-for-adaptive-high-speed-machining-using-cnc-software/

These purple lines are the link back moves. In this case, we are cutting in a single direction, so the green lines are cutting moves, and the purple lines are the link moves posted at the "max feed rate" value.

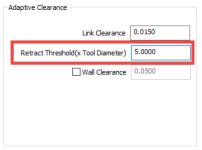

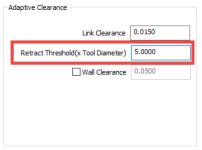

Use the link clearance ( Micro lifts ) to adjust how much the tool moves up for it's non-cutting link back move.

You can adjust this value ( minimal curvature radius ) to adjust the adaptive " roll in" size. Make this number bigger and you'll see larger arc in moves, make this number smaller the arc in moves will be smaller.

If you are using 3D adaptive toolpaths ( 3D advanced roughing ) you can control the tool keep down setting with the retrack threshold. Making this number bigger will force the tool to reposition while down. Making this number smaller will force the tool to clearance for it's link back moves.

For additional information on high speed machining concepts for 3 Axis Milling, watch this video.

--

If there is anything else I can help with on this topic, please let me know.