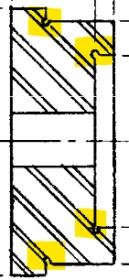

The inserts used turn the OD and Bore the ID always have a radius tip. Even if I program a perfect 90 degree angle the corner will always have a radius the size of my insert (either .031 or .015). On some applications I can’t have that small radius because the part needs to fit flush with another component and that small radius would be in the way. So I need a tool that can go in there and create a small dip to break off the rounded corner. The image I attached has an example of this. A lot of times it can be accomplished with a small grooving tool a .125 grooving tool is to big. Do any of you know of any tools I can use to achieve this? On OD I can usually get a away with a cutoff tool, but any suggestions for ID corners. Some parts have a bore depth of .125, so this tool would have to be way smaller. TIA!!

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Breaking off rounded corners

- Thread starter Kratos

- Start date

- Replies 7

- Views 1,430

706jim

Titanium

- Joined

- Jun 14, 2006

- Location

- Thunder Bay Canada

I recall seeing an Iscar video where they produced this sort of relief with one of their standard tools.

tonymor

Aluminum

- Joined

- Feb 9, 2017

- Location

- Chambersburg PA USA

We use DNMG tips to finish the OD. Just do an undercut 2x the tip radius.

1/2" RH MDJN Tri-Lock Tool Holder

Plenty of boring bars out there that you can do the same on the ID.

3/8" RH SDUCR Boring Bar For DCMT Inserts

1/2" RH MDJN Tri-Lock Tool Holder

Plenty of boring bars out there that you can do the same on the ID.

3/8" RH SDUCR Boring Bar For DCMT Inserts

DouglasJRizzo

Titanium

- Joined

- Jun 7, 2011

- Location

- Ramsey, NJ.

I usually finish the contour and then head back in with a sharp nosed insert and gently relieve the back of the bore.

DNMG, VNMG etc..

Some mfg's make a dedicated tool that's kicked on a 45deg to do plunge style undercuts also.

But if it's just a corner relief, then use a VNMG tool to go in and scallop it out. There are standard RH and LH tools as well as some VNMG holders that are on like a 117deg or something.

Same goes for the ID bars.

Some mfg's make a dedicated tool that's kicked on a 45deg to do plunge style undercuts also.

But if it's just a corner relief, then use a VNMG tool to go in and scallop it out. There are standard RH and LH tools as well as some VNMG holders that are on like a 117deg or something.

Same goes for the ID bars.

Booze Daily

Titanium

- Joined

- Sep 18, 2015

- Location

- Ohio

Google "45 degree undercut tool holder"

There's a bunch to choose from.

There's a bunch to choose from.

Similar threads

- Replies

- 29

- Views

- 2K

- Replies

- 25

- Views

- 2K

- Replies

- 26

- Views

- 3K