Utry2win

Aluminum

- Joined

- Aug 17, 2011

- Location

- Lakeland, FL

2000 Charmilles Robofil 330F

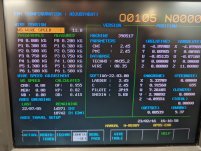

Just purchased it used. Got it hooked up to power and full of water, new filters installed. Fired it up, it is immediately shows Z axis over travel. If you attempt to jog any axis’ or switch to a mode such as REF home, I get a “2155 Water full compensation in progress”. All axis will move in any direction, with the exception of -Z for obvious reasons of it’s already in -Z overtravel.

Any ideas or tips?

I drained a little water from the dirty tank, thinking maybe too much in the machine, but that did not solve anything.

Just purchased it used. Got it hooked up to power and full of water, new filters installed. Fired it up, it is immediately shows Z axis over travel. If you attempt to jog any axis’ or switch to a mode such as REF home, I get a “2155 Water full compensation in progress”. All axis will move in any direction, with the exception of -Z for obvious reasons of it’s already in -Z overtravel.

Any ideas or tips?

I drained a little water from the dirty tank, thinking maybe too much in the machine, but that did not solve anything.

Last edited: