How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cincinnati Cinedo 210-14 Vertical

- Thread starter Harri89

- Start date

- Replies 46

- Views 13,167

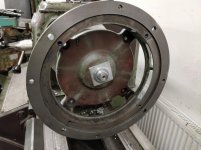

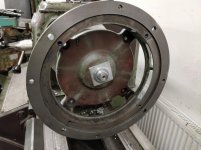

When i Turn the gear by hand which is in the picture, what motor turns. There or somewhere is something wrong with bearing. It wont Turn smoothly and makes noise.

Oil is already drained, it also looked alot thicker than Mobil dte medium which i have for it now.

What do you mean by riser plate?

The big plate where motor is mounted?

Yes, take the nut off and inspect the bearings for bad track marks.

Set the bearings at .002 cold. ( end play back and forth ) Make sure the gear on the motor has a good woodruff key, no roll over.. Make sure the gear on the motor is line up with idler gear. Full tooth side to side.

Last edited:

When i Turn the gear by hand which is in the picture, what motor turns. There or somewhere is something wrong with bearing. It wont Turn smoothly and makes noise.

Oil is already drained, it also looked alot thicker than Mobil dte medium which i have for it now.

What do you mean by riser plate?

The big plate where motor is mounted?

Yes, take the nut off and inspect the bearings for bad track marks. This gears have broken on other machines.

Paolo_MD

Stainless

- Joined

- Apr 6, 2013

- Location

- Damascus, MD

I'm unable to hear any tel-tale sound in the videos. Just some noise from worn gears with probably too mach play between meshing teeth.

I think it would be a good idea to run the motor and listen for unusual noises at operating speed.

If the bevel gears position can be adjusted, bringing them slightly closer could reduce a bit the noise. Do not bring them too close, otherwise you make the situation much worse.

Keeping or changing the baring: at what speed does it rotate? Is a replacement still readily available? How much does it cost?

If cheap and readily available, or it rotates at high speed, I would lean toward changing it. Otherwise, I bet it could survive a few decades of hobby use.

Paolo

I think it would be a good idea to run the motor and listen for unusual noises at operating speed.

If the bevel gears position can be adjusted, bringing them slightly closer could reduce a bit the noise. Do not bring them too close, otherwise you make the situation much worse.

Keeping or changing the baring: at what speed does it rotate? Is a replacement still readily available? How much does it cost?

If cheap and readily available, or it rotates at high speed, I would lean toward changing it. Otherwise, I bet it could survive a few decades of hobby use.

Paolo

I used a dial indicator to sweep the motor flange contact area and its tilted 0.1mm, i assume this misalignment can make also some noise in the gears. The motor mount flange has been fixed by someone and isnt been a 100% succes

I think i will straighten it up with lathe perendicular to the shaft, dont think 0.1mm will effect gear alignment axially significantly.

I think i will straighten it up with lathe perendicular to the shaft, dont think 0.1mm will effect gear alignment axially significantly.

Last edited:

Some bevel gears are made as a match set. Look for marks on the edge of the gears and see if there is two punch marks on one set and one punch mark on the other. not sure of yours will have them. Spiral bevels have to be set with backlash in them. Those will heat up if too close of a mesh. Just saying a word or so about bevel gears. Yours may not have marks on the gear edge.

Make sure the flat mounting surfaces do not have mushroom spots on them. Fill smooth. If you have impression blue for the gears will tell you have the gears are meshing. It should leave full contact to the gears.

Make sure the flat mounting surfaces do not have mushroom spots on them. Fill smooth. If you have impression blue for the gears will tell you have the gears are meshing. It should leave full contact to the gears.

The bevel gears had full contact to one direction, i have it now back togheter and everything feels smooth so far. I need to repair the motor cooling fan and true up the motor mounting flange.

I filled vertical head with fresh oil and rotated the motor what is top of the machine, no oil circulation to vertical head feed box what is on right side. I saw there copper pipes and i think they are for lubrication. I think now that it gets lubricated by knee oil pump

I neee to wait for now to get the knee feed motor back and running and fill the knee with fresh oil and see if it starts to lubricate also the head feed box.

I filled vertical head with fresh oil and rotated the motor what is top of the machine, no oil circulation to vertical head feed box what is on right side. I saw there copper pipes and i think they are for lubrication. I think now that it gets lubricated by knee oil pump

I neee to wait for now to get the knee feed motor back and running and fill the knee with fresh oil and see if it starts to lubricate also the head feed box.

I have rear control on this machine and when i was searching the cause of the noise, i managed to pull out the rapid traverse lever and screw the connecrion what engages front and rear levers.

I needed to pull out the feed gearbox to see whats wrong with it. Here i have some pictures for you. The gearbox itself is really compact piece!

Here are the pieces which engages front and rear levers.

Gearbox

I needed to pull out the feed gearbox to see whats wrong with it. Here i have some pictures for you. The gearbox itself is really compact piece!

Here are the pieces which engages front and rear levers.

Gearbox

I removed the mounting flange from the motor and took a closer look. I dont know what has happened to it because it has been repaired. Maybe someone dropped the motor to floor when removed and broke it.

There are these raised areas on the outer ring, are they factory made to get the gear running Clearance right?

There is also the opening for the fan, opening is 180' degrees. It faced upwards and that doesnt seem a logic position to me, i would put it downards because chipz, coolant etc can get there.

Maybe someone installed the motor in wrong position and the gear mesh clearance is too small which makes noise + the motor shaft misalignemnt.

I have now rapid traverse linkage working again and installed feed box back. Took out oil filter and it looks good. I will just clean it, its now soaked in degreaser.

There are these raised areas on the outer ring, are they factory made to get the gear running Clearance right?

There is also the opening for the fan, opening is 180' degrees. It faced upwards and that doesnt seem a logic position to me, i would put it downards because chipz, coolant etc can get there.

Maybe someone installed the motor in wrong position and the gear mesh clearance is too small which makes noise + the motor shaft misalignemnt.

I have now rapid traverse linkage working again and installed feed box back. Took out oil filter and it looks good. I will just clean it, its now soaked in degreaser.

Had some serious problems with chatter when turning the mounting flange.

First time machining something like this, the spots on outer edge was really hard

I tries different speeds, feeds, added live center, cutting oil. Raised tool height upwards to get more pressure Nothing helped.

I switched ccmt0904 to a cnmg1208 and dropped rpm to 45 and increased feed to 0.51mm/rev, cutting depth approx. 0.1mm. Results was amazing, atleast compared to above.

The hard spots are still slightly above the rest of the surface. I will do a test fit and leave it as is, if its "OK"

First time machining something like this, the spots on outer edge was really hard

I tries different speeds, feeds, added live center, cutting oil. Raised tool height upwards to get more pressure Nothing helped.

I switched ccmt0904 to a cnmg1208 and dropped rpm to 45 and increased feed to 0.51mm/rev, cutting depth approx. 0.1mm. Results was amazing, atleast compared to above.

The hard spots are still slightly above the rest of the surface. I will do a test fit and leave it as is, if its "OK"

Got the feed motor back and running, still sounds loud to my ears, the shaking is away and and its quieter than it was.

I noticed that if i push from the cooling fan the shaft moves axially towards the machine. There was a "wave washer" between the bearing and the housing.

The motor runs really nice away from the machine and when i runned the mill feed box with cordless drill, it was silent.

I am thinking that maybe the axial play makes some noise when its running and the helical gears makes axial force which moves the motor shaft back and forth?

Motor running : YouTube

Motor running in place : YouTube

Also i still dont see any lubrication in this:

I noticed that if i push from the cooling fan the shaft moves axially towards the machine. There was a "wave washer" between the bearing and the housing.

The motor runs really nice away from the machine and when i runned the mill feed box with cordless drill, it was silent.

I am thinking that maybe the axial play makes some noise when its running and the helical gears makes axial force which moves the motor shaft back and forth?

Motor running : YouTube

Motor running in place : YouTube

Also i still dont see any lubrication in this:

Similar threads

- Replies

- 22

- Views

- 609

- Replies

- 6

- Views

- 257

- Replies

- 55

- Views

- 3K