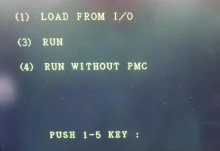

I booted the machine several times today and 1st time I was in EDIT, second AUTO and third JOG. Each time I rebooted after that, I was always in JOG.

Leaving the machine off for 20 minutes, the boot came back to EDIT. I have had MDI come up in the past, so completely random.

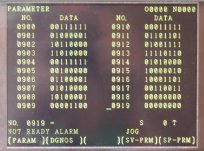

None of the values changed during this process.

The buttons all set the appropriate LEDs on the console but did not change the any of the registers below.

X021 00001000

G104 00000000

G121 00101110

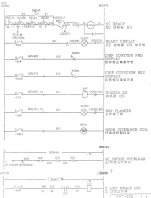

However some new advancement on this. I have a button on the console that says EM - The manual says," Press this button to release the EM alarm if over-travel. And choose any axis direction would do the feed motion of any axis. "

When I press this button with the E-Stop out, A contractor comes in and on releasing I get error 434 and the buzzer - The servo drive comes up with A -> Z axis error.

This could mean that under a fault conditions, a lot of 'normal' things are disabled like the mode options.

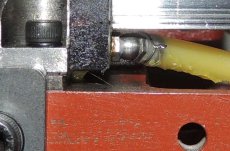

It is a long shot, but was wondering if the Z Axis brake could be stuck.