bengineer08

Plastic

- Joined

- Jun 17, 2022

- Location

- Northern KY / Cincinnati area

Hello all,

I've got a G71 external rouging issue I can't figure out. Running on a Miyano lathe, Fanuc 0T. Everything seems to run great, until it gets to the end of the roughing cycle, then it immediately makes a bee line for X0 Z0. I anticipate it should be going to X 30 Z5, but no. It's likely I'm programming it wrong (I'm teaching myself), but this looks very similar to the examples I've dug up. I keep looking over and over the gcode and I don't see where it thinks its supposed to be going there. If anyone could take a look, I'd greatly appreciate it. I think it happens on the G70 as well. Z zero is the front of the part.

05555

G21 G80 G40;

T0101;

G50 S2500;

G96 S525 M03;

G00 X30.0 Z5.0;

G01 Z0.01 F01;

X-0.5 F0.05; (FACING)

G00 X30.0 Z5.0;

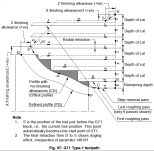

G71 U1.0 R1.0;

G71 P100 Q200 U0.2 W0.05 F0.1;

N100 G00 X14.8;

G01 G42 Z0 F0.2;

X15.8 Z-0.5;

Z-17.0;

X20.0 Z-20.64;

Z-25.0;

X25.0;

Z-38.0;

X30.0;

N200 G40 X30 Z5.0 F20.0;

G70 P100 Q200;

G28 U0 W0;

M05;

G97;

M30;

I've got a G71 external rouging issue I can't figure out. Running on a Miyano lathe, Fanuc 0T. Everything seems to run great, until it gets to the end of the roughing cycle, then it immediately makes a bee line for X0 Z0. I anticipate it should be going to X 30 Z5, but no. It's likely I'm programming it wrong (I'm teaching myself), but this looks very similar to the examples I've dug up. I keep looking over and over the gcode and I don't see where it thinks its supposed to be going there. If anyone could take a look, I'd greatly appreciate it. I think it happens on the G70 as well. Z zero is the front of the part.

05555

G21 G80 G40;

T0101;

G50 S2500;

G96 S525 M03;

G00 X30.0 Z5.0;

G01 Z0.01 F01;

X-0.5 F0.05; (FACING)

G00 X30.0 Z5.0;

G71 U1.0 R1.0;

G71 P100 Q200 U0.2 W0.05 F0.1;

N100 G00 X14.8;

G01 G42 Z0 F0.2;

X15.8 Z-0.5;

Z-17.0;

X20.0 Z-20.64;

Z-25.0;

X25.0;

Z-38.0;

X30.0;

N200 G40 X30 Z5.0 F20.0;

G70 P100 Q200;

G28 U0 W0;

M05;

G97;

M30;