This is purely a WAG (wild-ass guess) on my part, just letting my imagination go with what the clues the pictures provide.

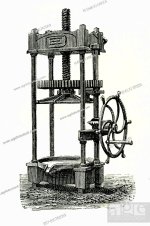

Whatever the stand was built for, it was a lighter-duty piece of equipment judging by the legs. The spout on the top might be a clue that a press (or other piece of equipment) for extracting a liquid was mounted on the top. The 'double D" boss in the bottom shelf and the holes in the bottom shelf support that same theory. A press with a gear-tooth rack or a press screw with two flats that needed to extend down from the top of the base when in use might be a possibility. The "double D" geometry of the hole could allow either a rack or a screw with two flats on it (to keep it from turning, same idea as the moveable jaw on a pipe wrench) to pass thru the 'shelf'.

The fact the 'shelf' has so many holes in it also is a clue that whatever the base was used for involved a liquid. Whatever the piece of equipment was, it was used for something that might get sloppy and have whatever liquid was being pressed dripping down onto the shelf. Whatever the liquid was, the designers of the equipment did not want it accumulating on the shelf.

The equipment that was mounted on the base likely did not require the persons using it to pull hard on levers (as with a hand operated press), given the design of the legs. The legs do not appear to extend too far beyond the perimeter of the top casting, nor do they have any flat pads for bolting the base to the floor. I do see what looks like a smaller diameter hole on the 'apex' of the flared-out bottom of one leg, but this would not give a really solid anchorage if pulling hard on a lever to operate the equipment was required.

Possible thoughts: might have been a light-duty press for seating lids on cans (such as used to hold paint and other liquids). This type lid is called a 'friction lid'. Rather than have someone smacking lids to seat and seal them with a mallet (and risking denting the cans), a light-duty press might have been used. If the cans were containing some liquid such as paint, varnish, lubricants, or perhaps honey (years ago, honey was sold by larger producers in the same type cans as paint), then the base of the hand press would have a spout for carrying off any spillage.

The fact the "D" hole in the boss in the shelf is offset from the center of the top speaks of a light duty press. Something on the order of a 'bottle capper', only built a bit heavier for handling maybe 1 gallon steel cans. The spout was not intended to be part of any actual process, but simply to route any spillage to a bucket or other catchment rather than let it accumulate and slop over the edge of the top of the base.