RCPDesigns

Hot Rolled

- Joined

- Sep 3, 2014

- Location

- Atlanta GA.

I'm starting to put the mill back together. I fit the spindle and measured the clearance as described in other forum posts. I found right about 170 thou. The strange thing is that the thrust ring is 186 thou. I'm fairly certain it is not original as there is no "35" stamped on it anywhere. Almost every single part of my mill has "35" stamped somewhere. The rear thrust ring has "35" stamped on it. I assume the mill had clearance issues and the previous owner's solution was to make a new ring.

So... using the formula,

gap - thrust ring + 0.006 = shim needed

0.170 - 0.186 + 0.006 = -0.010

Which, I think, means I have 10 thou too much clearance. First, is that correct and second, is this going to cause a problem? My guess would be that it will allow the spindle to move up/down/left/right since it will not be seated all the way into the taper. If that is the case, my options are?

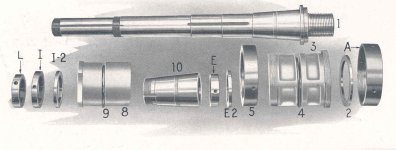

Here's a picture of the progress so far... and no, I didn't forget the bull gear. I'm just mocking things up right now to get some ideas for how I'm going to get power to it.

So... using the formula,

gap - thrust ring + 0.006 = shim needed

0.170 - 0.186 + 0.006 = -0.010

Which, I think, means I have 10 thou too much clearance. First, is that correct and second, is this going to cause a problem? My guess would be that it will allow the spindle to move up/down/left/right since it will not be seated all the way into the taper. If that is the case, my options are?

Here's a picture of the progress so far... and no, I didn't forget the bull gear. I'm just mocking things up right now to get some ideas for how I'm going to get power to it.

Attachments

Last edited: