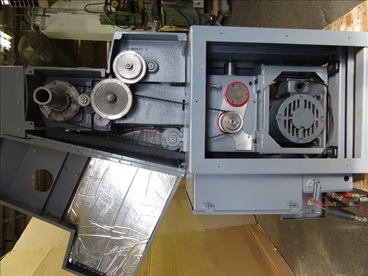

Guess one could put add on the Facebook marketplace.

Lathe and grinder stuff.

Will pay a machine tech/clean up type person to hone surface rust and appraise machine values. $20 per hour/ must bring own tools for the work.

* if I saw this ad on Facebook and it was not too far away, I would go to have a look and take the necessary tools and expect to put 4 hours into the job. ( fine flat file, flat hones, oil, solvent, wire brush, some picks to clean chips, couple of buckets, sack of rags, some laytex gloves. a couple of garbage bags, a wrench set, screwdrivers, an Allen wrench set, flashlight.. X you don't allow power wire brushing hand wheel dials, mostly power wire brushing is a no, no.

"You might ask such a person What tools or equipment would you bring for the work?

-> skip someone who does not know what tools.

One way to clean surface rust is to oil hone the surface (very fast and easy).

Someone that could be helpful should at least know that.

If you have a young person that doesn't mind a little elbow grease, I could give instruction. You don't want a teenager or younger around machines that don't have the power source turned off.

Buy a few fine-side hones and a quart of non-detergent oil (lowest price Auto store oil is fine for this).. and some quality latex gloves. Wet a flat surface with a little oil and with carefully figure 8 motion hone all you can. wipe off all the oil and abrasive grit and then travel a machine movement to the next area to be honed. Flat things like angle plates often come out very good. You want to use new condition hones, not ones that have been abused like for knife sharpening.

A little rust is often the excuse to lowball a price, and machine flippers want to buy everything for scrap price or less.

The lathe will sell much better if it is under power-> but a lathe is dangerous so f you know little about a lathe you should not even try to start it.

2000 to $3500 for the lathe seems in the right ballpark for the lathe

cleaned up perhaps $4500..

But bigger lathes are not easy to sell because often they only sell to a machine shop. Likely your Husband's tools have some flat hones, so you might try the figure 8 oil honing on some of the angle plates. If they are not rust pitted it may take 10 minutes each....and yes there are rust removal chemicals with vinegar being one..But the oil honing is the quick, accurate, proper fix for minor surface rust.