MAGNOMOLDES

Plastic

- Joined

- Sep 27, 2023

O0100

N10 G11 (TEC, GEAR1) => “GEAR1” IS TECHNOLOGY NAME

N20 G11 (WIR, LT25) => “LT25” WIRE NAME IN MACHINE WIREBOX

N30 G10 P16 R-0.02 => (R=-0.02mm corner rounding radius minimum)

N40 G90 G21 => ABSOLUTE COORDENATE & MM

N50 G0 X0 Y0 => RAPID TRAVERSE TO ORIGIN X0, Y0

N60 G92 X0 Y0 I26 J15.5 (X0 Y0 determined the zero point from the workpiece; I=26mm thickness of plate and 15.5mm the height from the face of workpiece to the wire)

N70 M60 (wire thread)

N80 S502 H20 (S502= FINISHING H=20MM THICKNESS WORKPIECE)

N90 G1 G42 X-1.4237 Y8.1399

N100 G2 X1.4237 Y8.1399 I1.4237 J-8.1399

N110 G1 X2.8301 Y9.5912

N120 G2 X4.7808 Y8.7832 I-2.8301 J-9.5912

N130 G1 X4.7491 Y6.7625

N140 G2 X5.8351 Y5.8512 I-4.7491 J-6.7625

N150 G1 X7.8195 Y6.2334

N160 G2 X8.9540 Y4.4526 I-7.8195 J-6.2334

N170 G1 X7.7690 Y2.8156

N180 G2 X8.1360 Y1.4461 I-7.7690 J-2.8156

N190 G1 X9.9807 Y0.6210

N200 G2 X9.8886 Y-0.-1.4885 I-9.9807 J-0.6210

N210 G1 X7.9790 Y-2.1497

N220 G2 X7.4941 Y-3.4820 I-7.9790 J2.1497

N230 G1 X8.5319 Y-5.260

N240 G2 X7.2465 Y-6.8912 I-8.5319 Y5.260

N250 G1 X.5.3030 Y-6.3375

N260 G2 X4.1416 Y-7.1507 I-5.3030 J6.3375

N270 G1 X3.9917 Y-9.1664

N280 G2 X1.9834 Y-9.8013 I-3.9917 J9.1664

N290 G1 X0.7089 Y-8.2330

N300 G2 X-0.7089 Y-8.2330 I-0.7089 J8.2330

N310 G1 X-1.9834 Y-9.8013

N320 G2 X-3.9971 Y-9.1664 I1.9834 J9.8013

N330 G1 X-4.1416 Y-7.1507

N340 G2 X-5.3030 Y-6.3375 I4.1416 J7.1507

N350 G1 X-7.2465 Y-6.8912

N360 G2 X-8.5319 Y-5.2160 I7.2465 Y6.8912

N370 G1 X-7.4941 Y-3.4820

N380 G2 X-7.9790 Y-2.1497 I7.4941 J3.4820

N390 G1 X-9.8886 Y-1.4885

N400 G2 X-9.9807 Y0.6210 I9.8886 J1.4885

N410 G1 X-8.1360 Y1.4461

N420 G2 X-7.7690 Y2.8156 I8.1360 J-1.4461

N430 G1 X-8.9540 Y4.4526

N440 G2 X-7.8195 Y6.2334 I8.9540 J-4.4526

N450 G1 X-5.8351 Y5.8512

N460 G2 X-4.7491 Y6.7625 I5.8351 J-5.8512

N470 G1 X-4.7808 Y8.7832

N480 G2 X-2.8301 Y9.5912 I4.7808 J-8.7832

N490 G1 X-1.4237 Y8.1399

N500 G1 G40

N510 G1 X0 Y0

N520 M50

N520 M30

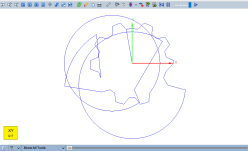

May someone confirm if this is the way to program point to point once I can take each point aided by AUTOCAD?

N10 G11 (TEC, GEAR1) => “GEAR1” IS TECHNOLOGY NAME

N20 G11 (WIR, LT25) => “LT25” WIRE NAME IN MACHINE WIREBOX

N30 G10 P16 R-0.02 => (R=-0.02mm corner rounding radius minimum)

N40 G90 G21 => ABSOLUTE COORDENATE & MM

N50 G0 X0 Y0 => RAPID TRAVERSE TO ORIGIN X0, Y0

N60 G92 X0 Y0 I26 J15.5 (X0 Y0 determined the zero point from the workpiece; I=26mm thickness of plate and 15.5mm the height from the face of workpiece to the wire)

N70 M60 (wire thread)

N80 S502 H20 (S502= FINISHING H=20MM THICKNESS WORKPIECE)

N90 G1 G42 X-1.4237 Y8.1399

N100 G2 X1.4237 Y8.1399 I1.4237 J-8.1399

N110 G1 X2.8301 Y9.5912

N120 G2 X4.7808 Y8.7832 I-2.8301 J-9.5912

N130 G1 X4.7491 Y6.7625

N140 G2 X5.8351 Y5.8512 I-4.7491 J-6.7625

N150 G1 X7.8195 Y6.2334

N160 G2 X8.9540 Y4.4526 I-7.8195 J-6.2334

N170 G1 X7.7690 Y2.8156

N180 G2 X8.1360 Y1.4461 I-7.7690 J-2.8156

N190 G1 X9.9807 Y0.6210

N200 G2 X9.8886 Y-0.-1.4885 I-9.9807 J-0.6210

N210 G1 X7.9790 Y-2.1497

N220 G2 X7.4941 Y-3.4820 I-7.9790 J2.1497

N230 G1 X8.5319 Y-5.260

N240 G2 X7.2465 Y-6.8912 I-8.5319 Y5.260

N250 G1 X.5.3030 Y-6.3375

N260 G2 X4.1416 Y-7.1507 I-5.3030 J6.3375

N270 G1 X3.9917 Y-9.1664

N280 G2 X1.9834 Y-9.8013 I-3.9917 J9.1664

N290 G1 X0.7089 Y-8.2330

N300 G2 X-0.7089 Y-8.2330 I-0.7089 J8.2330

N310 G1 X-1.9834 Y-9.8013

N320 G2 X-3.9971 Y-9.1664 I1.9834 J9.8013

N330 G1 X-4.1416 Y-7.1507

N340 G2 X-5.3030 Y-6.3375 I4.1416 J7.1507

N350 G1 X-7.2465 Y-6.8912

N360 G2 X-8.5319 Y-5.2160 I7.2465 Y6.8912

N370 G1 X-7.4941 Y-3.4820

N380 G2 X-7.9790 Y-2.1497 I7.4941 J3.4820

N390 G1 X-9.8886 Y-1.4885

N400 G2 X-9.9807 Y0.6210 I9.8886 J1.4885

N410 G1 X-8.1360 Y1.4461

N420 G2 X-7.7690 Y2.8156 I8.1360 J-1.4461

N430 G1 X-8.9540 Y4.4526

N440 G2 X-7.8195 Y6.2334 I8.9540 J-4.4526

N450 G1 X-5.8351 Y5.8512

N460 G2 X-4.7491 Y6.7625 I5.8351 J-5.8512

N470 G1 X-4.7808 Y8.7832

N480 G2 X-2.8301 Y9.5912 I4.7808 J-8.7832

N490 G1 X-1.4237 Y8.1399

N500 G1 G40

N510 G1 X0 Y0

N520 M50

N520 M30

May someone confirm if this is the way to program point to point once I can take each point aided by AUTOCAD?