HiltzMachining

Plastic

- Joined

- Dec 4, 2018

- Location

- Aroostook County

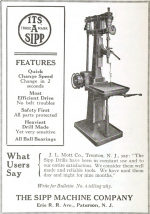

I picked up a very old drill press made by a company called SIPP. I saved it from the scrap yard after it came out of a closed paper mill near Dover, Maine. It is an extremely handy rig, with a full knee and an additional 10” travel where the quill mounts to the column. This is a very old school machine but it has a unique way that it changes spindle speeds. You can change speeds on the fly because the selector handle for the speeds moves the flat belt up and down the range of speeds. I thought it was a really cool way to do it.

It weighs over 700 pounds, so it is very rigid for a drill press.

I have a serious problem because I am completely addicted to finding and saving vintage American Iron machine tools.

I paid $200 for the machine and after an hour cleaning it up I have since been using it for lots of fabrication projects.

I kind of documented the process of bringing it home. I want to do a full tear down and restore on it and document the process.

I saw on the forum that someone else found one of these as disassembled it to bring it into his basement. It would be neat to see if he ever was able to completely restore it.

It weighs over 700 pounds, so it is very rigid for a drill press.

I have a serious problem because I am completely addicted to finding and saving vintage American Iron machine tools.

I paid $200 for the machine and after an hour cleaning it up I have since been using it for lots of fabrication projects.

I kind of documented the process of bringing it home. I want to do a full tear down and restore on it and document the process.

I saw on the forum that someone else found one of these as disassembled it to bring it into his basement. It would be neat to see if he ever was able to completely restore it.