Michael_h359

Plastic

- Joined

- Aug 29, 2022

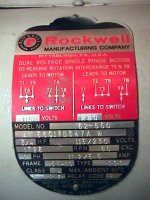

Thank you all for sharing your knowledge. I went and looked at a Rockwell 21-100 today that looked very scary in the pictures, has some rust issues as it was stored outside for some time. In person I was able to look at the ways and operate the table and she felt very tight yet traveled smoothly. It is a 115 volt 1/2 HP motor that sounded solid and spun smooth. I was able to negotiate to $700. Came with a set of R8 collets a clamping set and spare 230 volt motor as well. Extremely excited on the purchase and will upload pictures when I can. Going to need some work before she is operational. Thank you everyone and a special thanks to "Wood2Steel" for guiding me in the right direction!