Ohio Mike

Titanium

- Joined

- Oct 30, 2008

- Location

- Central Ohio, USA

Good Day Everyone,

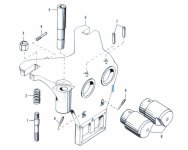

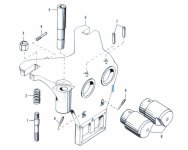

So after some years of searching I finally able to locate and purchase a really nice well cared for vertical head for my 2H mill. Its the Standard High Speed Adjustable with the drive gear. As an added bonus the purchase included the parking attachment. Actually I found it because the seller sold me a K&T model H dividing head and we got to talking about K&T mills. Turns out he had the head and parking attachment on a pallet and hand't gotten around to figuring out which model it went on. So for those with the parking attachment I have a question since I'm missing some hardware. The diagram indicates longer studs were installed (around an inch longer) and the bracket appears to hang off of them via an "eccentric hex block" which is part #3 in the diagram. So my question is was the eccentric there just to adjust for casting differences and provide 6 positions for some lateral adjustment? I need to reproduce them or something similar. The block would need to slide up and down slightly has the nuts were tightened on the studs to lock the overarms. The parts breakdown below is from K&T publication AR-30.

Thanks, Mike

So after some years of searching I finally able to locate and purchase a really nice well cared for vertical head for my 2H mill. Its the Standard High Speed Adjustable with the drive gear. As an added bonus the purchase included the parking attachment. Actually I found it because the seller sold me a K&T model H dividing head and we got to talking about K&T mills. Turns out he had the head and parking attachment on a pallet and hand't gotten around to figuring out which model it went on. So for those with the parking attachment I have a question since I'm missing some hardware. The diagram indicates longer studs were installed (around an inch longer) and the bracket appears to hang off of them via an "eccentric hex block" which is part #3 in the diagram. So my question is was the eccentric there just to adjust for casting differences and provide 6 positions for some lateral adjustment? I need to reproduce them or something similar. The block would need to slide up and down slightly has the nuts were tightened on the studs to lock the overarms. The parts breakdown below is from K&T publication AR-30.

Thanks, Mike