Actually, there is a fundamental missing piece of technology.

3D non-contact gauging is not yet available in the industrial domain.

2D sure, but at the current SIAMS no 3D was being shown, and there was some very over-the-top stuff on display.

Specifically, both the Agie and Trumpf subtractive (ie. laser) systems run open loop. That is the material removal rates are calculated in the CAM, and they're non-linear, so FEM or something simular is involved in guessing the optimum dwell times. Run the CAM, then can check your vaporized away piece against the wished outcome and adjust your model accordingly. For the record the floor reps said the machines stay dialed in, and they were showcaseing eff'n amazing product

The situation with additive systems is somewhat worse. It is also non-linear. So until reliable, inexpensive, precise 3D vision exists, these systems will not be able to cut (or add) to plan, but instead run open loop to model. And in practise, theory and practise are different.

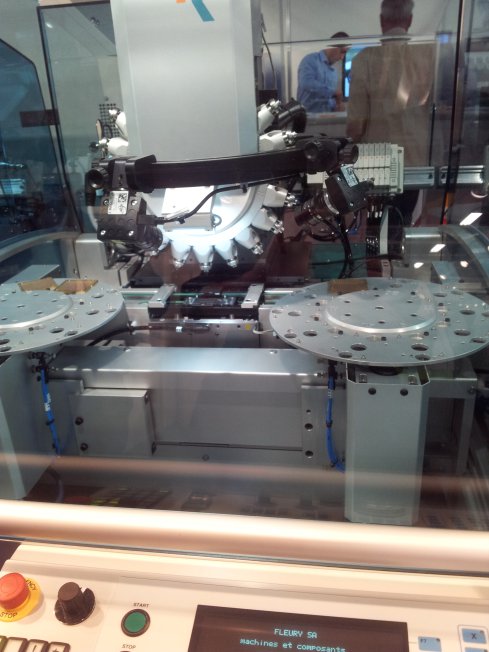

Anyhoo, in the real world of plain old cut the metal away techology, the Robots definitely have the upper hand. Check out these modular inline robotic cells.