LikesOldMachines

Plastic

- Joined

- Feb 25, 2020

- Location

- Boston

*Apologies if this isn't the correct location - I'm new to this forum* I have two questions regarding Linley jig borers:

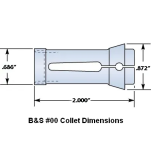

1) Can anyone confirm if the Linley "split-from-both-end" style collets of the later MK. 1A machines are the same taper as the Schaublin ESX/ER 25 style collet?

2) Can anyone confirm whether or not the spindle taper of the pre MK. 1A machines will accept the taper of the Schaublin ESX/ER 25 collet?

For context: I'm interested in purchasing a Linley MK. 1A (with dovetails) for the purpose of jig boring and occasional light milling, however, it is unclear from this source http://www.lathes.co.uk/linley/ whether or not the machines that come equipped with the longer split-from-one-end type will accept the later Schaublin style ESX collet. I'm asking because I've seen a couple jig borers for sale with the older style collet that, if it were the case that the taper were the same, I could use the later style collet and manufacture my own nosepiece. If that weren't the case, I guess I would have to wait for an MK. 1A to come up for sale with the later style collets already in hand. I've re-ground spindle tapers for milling machines before, but if they aren't compatible, it might just not be worth my time/effort to convert it.

Attached is a photo showing the old style on the left and the Schaublin ESX style on the right.

Please let me know if you can give me any further insight!

1) Can anyone confirm if the Linley "split-from-both-end" style collets of the later MK. 1A machines are the same taper as the Schaublin ESX/ER 25 style collet?

2) Can anyone confirm whether or not the spindle taper of the pre MK. 1A machines will accept the taper of the Schaublin ESX/ER 25 collet?

For context: I'm interested in purchasing a Linley MK. 1A (with dovetails) for the purpose of jig boring and occasional light milling, however, it is unclear from this source http://www.lathes.co.uk/linley/ whether or not the machines that come equipped with the longer split-from-one-end type will accept the later Schaublin style ESX collet. I'm asking because I've seen a couple jig borers for sale with the older style collet that, if it were the case that the taper were the same, I could use the later style collet and manufacture my own nosepiece. If that weren't the case, I guess I would have to wait for an MK. 1A to come up for sale with the later style collets already in hand. I've re-ground spindle tapers for milling machines before, but if they aren't compatible, it might just not be worth my time/effort to convert it.

Attached is a photo showing the old style on the left and the Schaublin ESX style on the right.

Please let me know if you can give me any further insight!