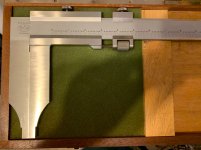

My father was a mechanical engineer and i was going through some of his things as he has passed. Just want to know if and what kind of value this might have. Looked on Ebay and seen similar offered at as much $500+. Thought ,maybe on forum such as this i can find out more information. Thank you

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking for value information Vintage Helios Stainless Steel Vernier Caliper. It is 0- 42.5"

- Thread starter ALAN D

- Start date

- Replies 19

- Views 1,670

moonlight machine

Diamond

- Joined

- Nov 19, 2007

- Location

- marysville ohio

I bought a 24" Mitutoyo for 75.00 Problem is most people can't read them. Figure out what you want, I may be interested.

RC Mech

Stainless

- Joined

- Jul 21, 2014

- Location

- Ontario, Canada

You need to look at “sold” prices. Anyone can offer unreasonable asking prices.

L Vanice

Diamond

- Joined

- Feb 8, 2006

- Location

- Fort Wayne, IN

It is not old enough to be an antique collectors' item. It is not modern enough (digital) to appeal to most potential users.

Old people (me) know how to use a vernier instrument; kids, not so much. But old eyes (mine) can't read a vernier without a loupe and good light. A 40 inch caliper is heavy, awkward to use, subject to temperature error and almost never useful. So it has sentimental value and could be hung on a wall. Cash value could be determined at auction. With luck, two people might want it.

Larry

Old people (me) know how to use a vernier instrument; kids, not so much. But old eyes (mine) can't read a vernier without a loupe and good light. A 40 inch caliper is heavy, awkward to use, subject to temperature error and almost never useful. So it has sentimental value and could be hung on a wall. Cash value could be determined at auction. With luck, two people might want it.

Larry

Joe Michaels

Diamond

- Joined

- Apr 3, 2004

- Location

- Shandaken, NY, USA

I agree with Larry Vanice: I also find that with age, I can no longer read a 'real' vernier caliper without using a magnifier & good light. I also agree that a 40 inch caliper is a bit hard to use and get accurate readings given its size and weight.

A little story: in December, 1985, I was working at a hydroelectric plant under construction, a bit north of Utica, NY (Hinkley Dam). It was bitterly cold. An engineer for the turbine manufacturer got ahead of himself in attempting to set position limit switches on an 84" diameter motor-operated butterfly valve. He wound up with the motor operator overtravelling, and crashed the gear train against a steel stop. Instead of a shaft key shearing (as we are taught in school about such things), the hub of a large cast iron bull gear blew apart. It failed from the corner of the keyway in the hub and about 36" worth of cast iron bull gear was in pieces. We were on a tight deadline to make first power before 12:01 on 1 January of 1986. Don't ask me why, but we were under the gun to get one unit 'synched' into the grid, if only for a few minutes before the New Year arrived. I volunteered to solve the mess with the bull gear failure. I found a local machine shop who could reverse engineer a gear out of steel plate. I brought them the chunks of the destroyed gear, and the shop owner handed me a large 'real' vernier caliper with a request that I get a good measurement of the shaft diameter the bull gear fit onto.

I returned to my motel and kept the vernier in my room with me so it would stay warm all night. I had my company truck's engine coolant heater plugged in all night as well. In the morning, I started the truck, heater full on, and went to breakfast. I did not put the vernier into the truck cab until the cab was nice and warm. I drove to the jobsite and brought in the vernier, wrapped in a blanket. It was a union jobsite, and I expected the millwrights to claim using the vernier to measure the shaft as their work. No one wanted anything to do with that vernier. I climbed up on a stepladder and stuck my head into the gearcase and used the vernier to get the shaft diameter. The millwright general foreman realized the situation and took another reading to confirm mine.

I then called the machine shop with the shaft diameter based on the vernier reading. The shop said they'd bore the gear hub accordingly. Come that evening, they had the gear ready for us. I brought the gear to the motel and lugged it up a flight of stairs and into my room. I put the gear in the bathroom, and all thru the night, kept waking to turn on the timed heat lamp in the bathroom. I wanted that gear as warm as possible. Come morning, same drill with the truck and going to breakfast while the truck warmed up. I wrapped the gear in blankets and got it lugged into the truck cab.

At the jobsite, we rushed it into the hydroelectric plant, and up onto the shaft it almost went. I was going on too hard for what it was. I called the machine shop. The owner laughed and said he had deliberately had the gear bored a few thousandths undersized. His reason was that he did not trust me or anyone else to take an accurate diameter reading with the vernier caliper. He said it was apparent I had taken an accurate reading (as confirmed by the millwright general foreman). I had to rush the gear back to the shop. He placed the gear in the coolant tank on his Blanchard grinder, reasoning the liquid in the tank would bring the gear to ambient temperature a lot quicker than in the open air. I went up the street and took my time with a second breakfast. The gear went onto a large Monarch engine lathe and was bored for a 'light drive fit' on the shaft. This time, it went on as it was supposed to.

I 'came up' using vernier calipers and vernier plates on instruments such as surveyor's transits and bevel protractors and the like. Nowadays, very few people know how to read a 'real vernier' caliper. Dial calipers took hold, and then digital calipers. I remember when I was a student at Brooklyn Technical HS, I had 3 years of machine shop courses, and one semester of 'inspection shop'. In both cases, reading a real vernier was a requirement. I also remember wanting a dial caliper of my own. I could not afford a new Helios dial caliper (as some of my classmates brought to school with them). I think a new Helios dial caliper was all of 14 bucks, which, at the time and to me as a HS student, was a lot of money. A classmate sold me a "Zeus" German made 'mauser type' vernier, used, from his father, or 5 bucks. I did a lot of work with that Zeus vernier caliper and still own it. Back then, I could read the vernier with no help from a magnifier.

I was asked a question recently as to what the most accurate form of sliding caliper is: vernier, dial, or digital. To my thinking:

-vernier calipers rely on the user to read them correctly, and things like parallax and other eyesight issues (let alone a lot of younger people being unable to do simple

math in their heads) weigh against the vernier

-dial calipers rely on a rack and pinion and gear train. Wear and backlash or a chip getting into the rack weigh against the dial caliper being the most accurate.

-digital 'direct reads', has no rack and pinion and gearing to worry about, no squinting to make out the lines on the 'plate, and the only variable is really the handling of the caliper by the user. So long as the scale is not messed up and the battery has charge, the digital caliper is it, hands down.

I found my self saying that I was 'sorry to have to say, but the digital caliper is the most accurate'. I have a 36" Mitutoyo vernier caliper and a 24" Brown & Sharpe vernier caliper. I've used them once or twice in the past 30 years on jobs like steam engine pistons for which I did not have a big enough micrometer. I'd always ask the person working with me to 'back up my reading'. I'd write my reading down on paper, and not say it aloud, and wait to hear what the other guy came up with. If we did not agree on the reading, we'd take them again and I'd take the caliper from the other guy and read it based on what he had it set at, and vice versa.

Nowadays, in the era of digital instruments, the need for a large 'real' vernier is not too prevailent. The instrument the OP has asked about is a fine instrument, no question there. However, as to value and use, both are limited these days. Working shops and inspection departments would likely not have that instrument, leaning towards digital instruments and keeping them in calibration. The people who might use this vernier are people doing historic or hobby type machine work, working on old steam or gas engines with fairly large cylinder bores. Otherwise, I'd suggest the OP take the lid off the box that instrument is in, replace it with a piece of clear acrylic, and hang the instrument in its 'glass case' on the wall with a nice engraved plaque memorializing his father.

A little story: in December, 1985, I was working at a hydroelectric plant under construction, a bit north of Utica, NY (Hinkley Dam). It was bitterly cold. An engineer for the turbine manufacturer got ahead of himself in attempting to set position limit switches on an 84" diameter motor-operated butterfly valve. He wound up with the motor operator overtravelling, and crashed the gear train against a steel stop. Instead of a shaft key shearing (as we are taught in school about such things), the hub of a large cast iron bull gear blew apart. It failed from the corner of the keyway in the hub and about 36" worth of cast iron bull gear was in pieces. We were on a tight deadline to make first power before 12:01 on 1 January of 1986. Don't ask me why, but we were under the gun to get one unit 'synched' into the grid, if only for a few minutes before the New Year arrived. I volunteered to solve the mess with the bull gear failure. I found a local machine shop who could reverse engineer a gear out of steel plate. I brought them the chunks of the destroyed gear, and the shop owner handed me a large 'real' vernier caliper with a request that I get a good measurement of the shaft diameter the bull gear fit onto.

I returned to my motel and kept the vernier in my room with me so it would stay warm all night. I had my company truck's engine coolant heater plugged in all night as well. In the morning, I started the truck, heater full on, and went to breakfast. I did not put the vernier into the truck cab until the cab was nice and warm. I drove to the jobsite and brought in the vernier, wrapped in a blanket. It was a union jobsite, and I expected the millwrights to claim using the vernier to measure the shaft as their work. No one wanted anything to do with that vernier. I climbed up on a stepladder and stuck my head into the gearcase and used the vernier to get the shaft diameter. The millwright general foreman realized the situation and took another reading to confirm mine.

I then called the machine shop with the shaft diameter based on the vernier reading. The shop said they'd bore the gear hub accordingly. Come that evening, they had the gear ready for us. I brought the gear to the motel and lugged it up a flight of stairs and into my room. I put the gear in the bathroom, and all thru the night, kept waking to turn on the timed heat lamp in the bathroom. I wanted that gear as warm as possible. Come morning, same drill with the truck and going to breakfast while the truck warmed up. I wrapped the gear in blankets and got it lugged into the truck cab.

At the jobsite, we rushed it into the hydroelectric plant, and up onto the shaft it almost went. I was going on too hard for what it was. I called the machine shop. The owner laughed and said he had deliberately had the gear bored a few thousandths undersized. His reason was that he did not trust me or anyone else to take an accurate diameter reading with the vernier caliper. He said it was apparent I had taken an accurate reading (as confirmed by the millwright general foreman). I had to rush the gear back to the shop. He placed the gear in the coolant tank on his Blanchard grinder, reasoning the liquid in the tank would bring the gear to ambient temperature a lot quicker than in the open air. I went up the street and took my time with a second breakfast. The gear went onto a large Monarch engine lathe and was bored for a 'light drive fit' on the shaft. This time, it went on as it was supposed to.

I 'came up' using vernier calipers and vernier plates on instruments such as surveyor's transits and bevel protractors and the like. Nowadays, very few people know how to read a 'real vernier' caliper. Dial calipers took hold, and then digital calipers. I remember when I was a student at Brooklyn Technical HS, I had 3 years of machine shop courses, and one semester of 'inspection shop'. In both cases, reading a real vernier was a requirement. I also remember wanting a dial caliper of my own. I could not afford a new Helios dial caliper (as some of my classmates brought to school with them). I think a new Helios dial caliper was all of 14 bucks, which, at the time and to me as a HS student, was a lot of money. A classmate sold me a "Zeus" German made 'mauser type' vernier, used, from his father, or 5 bucks. I did a lot of work with that Zeus vernier caliper and still own it. Back then, I could read the vernier with no help from a magnifier.

I was asked a question recently as to what the most accurate form of sliding caliper is: vernier, dial, or digital. To my thinking:

-vernier calipers rely on the user to read them correctly, and things like parallax and other eyesight issues (let alone a lot of younger people being unable to do simple

math in their heads) weigh against the vernier

-dial calipers rely on a rack and pinion and gear train. Wear and backlash or a chip getting into the rack weigh against the dial caliper being the most accurate.

-digital 'direct reads', has no rack and pinion and gearing to worry about, no squinting to make out the lines on the 'plate, and the only variable is really the handling of the caliper by the user. So long as the scale is not messed up and the battery has charge, the digital caliper is it, hands down.

I found my self saying that I was 'sorry to have to say, but the digital caliper is the most accurate'. I have a 36" Mitutoyo vernier caliper and a 24" Brown & Sharpe vernier caliper. I've used them once or twice in the past 30 years on jobs like steam engine pistons for which I did not have a big enough micrometer. I'd always ask the person working with me to 'back up my reading'. I'd write my reading down on paper, and not say it aloud, and wait to hear what the other guy came up with. If we did not agree on the reading, we'd take them again and I'd take the caliper from the other guy and read it based on what he had it set at, and vice versa.

Nowadays, in the era of digital instruments, the need for a large 'real' vernier is not too prevailent. The instrument the OP has asked about is a fine instrument, no question there. However, as to value and use, both are limited these days. Working shops and inspection departments would likely not have that instrument, leaning towards digital instruments and keeping them in calibration. The people who might use this vernier are people doing historic or hobby type machine work, working on old steam or gas engines with fairly large cylinder bores. Otherwise, I'd suggest the OP take the lid off the box that instrument is in, replace it with a piece of clear acrylic, and hang the instrument in its 'glass case' on the wall with a nice engraved plaque memorializing his father.

OlCat

Aluminum

- Joined

- Mar 17, 2008

- Location

- Lascassas, TN

Joe; I really enjoy your stories.

I too started into the surveying field as my first real job. I can vividly remember “turn left, read right” when learning to read the vernier on the transit. At the time, I learned on a 30 second gun and a 20 second gun. I cannot recall what brand of transit I learned on, but I think it was K&E.

Keep the faith

Bob

I too started into the surveying field as my first real job. I can vividly remember “turn left, read right” when learning to read the vernier on the transit. At the time, I learned on a 30 second gun and a 20 second gun. I cannot recall what brand of transit I learned on, but I think it was K&E.

Keep the faith

Bob

gustafson

Diamond

- Joined

- Sep 4, 2002

- Location

- People's Republic

The reason I prefer dials in production is that you can very quickly find the low spot for outside measurements, where digitals do not update quickly enough. This is impossible for verniers, so your rely on care and repetition, which takes time. I prefer digitals for inspection as you are usually not worried about speed as much, and they tell you the answer, rather than you looking three places to get it. IE 4 inches, 4 tenths of an inch and 31 thousandths etc digitals tell you 4.431 right in front of you. Same idiot who programmed 4.331 instead of 4.431 will read 4.331 as 4,431 on dial calipers.

I bought Mitutoyo 24 inch digitals for 500 bucks almost 30 years ago, they are fussy and the tape is detaching, but they still work and nothing I do with them cares for absolute accuracy. At the time verniers would have been 3 or 4 times that.

To the OP, problem with used measuring tools is it is hard to tell if they have been misused or are worn. One would not expect large calipers to pick up wear like 6 inch do.

New cheapie digitals are less than a grand at that size.

I bought Mitutoyo 24 inch digitals for 500 bucks almost 30 years ago, they are fussy and the tape is detaching, but they still work and nothing I do with them cares for absolute accuracy. At the time verniers would have been 3 or 4 times that.

To the OP, problem with used measuring tools is it is hard to tell if they have been misused or are worn. One would not expect large calipers to pick up wear like 6 inch do.

New cheapie digitals are less than a grand at that size.

M.B. Naegle

Diamond

- Joined

- Feb 7, 2011

- Location

- Conroe, TX USA

Dial and Digital calipers do get used the most, but I still like veneers for two reasons: Simple construction means less parts to fail should it get knocked around (and in my experience calipers are some of the most accident prone measuring tools in the shop due to their shape and how they get used for "everything)" The other reason that the OP wouldn't like is that they tend to be cheap. Digital or dial calipers the sizer of the OP's get pretty spendy, but a veneer set will be a fraction of the cost. In our shop, it's not often we need calipers over 12" long. It's a hard sell to buy a decent reliable digital or dial set that will only see daylight once a year, but the old Vernier set in the back of the tool crib work just fine, even if it takes you an extra minute to get a reading.

Joe Michaels

Diamond

- Joined

- Apr 3, 2004

- Location

- Shandaken, NY, USA

M.B. Naegle:

I agree with you: 'real' vernier calipers are the most rugged of the three types of 'slide caliper'. I've watched a number of youtubes of Pakistani machinists. These guys work on worn or broken parts of heavy construction equipment, farm tractors and heavy truck. Typically, they do build-up welding or joining of broken parts with stickj welding, then remachine the parts. These guys seem to use rules and spring calipers, or vernier calipers. No digital or dial calipers. These guys seem to read their verniers at a quick glance, no magnifiers or eyeglasses needed. Having a vernier caliper is a step up from the use of a rule and spring (or firm joint) calipers.

In the Pakistani shops and working conditions, very nearly everything seems to be patched together as few times over. Other than their cell phones, modern technology is not evident. Wiring for motors on their machine tools is sketchy at best, and welding is done in lathes with no sign of the ground clamp being anywhere in sight. One has to wonder what condition the headstock spindle bearings are in as a result. I do not think a digital or dial vernier would last too long in those shops. These guys use a piece of bent wire on a beat up surface gauge to setup work in 4 jaw chucks, probably because dial indicators were also considered a luxury or would not survive in those conditions. A basic vernier with no scales, no batteries, no rack-and-pinion and gear train, is the ideal thing for these guys.

While some of their repairs leave me wondering as to how long the repaired parts will hold together, I have a great deal of respect for the Pakistani mechanics and machinists. A simple vernier caliper is almost a luxury for those machinists, given what they have to work with. Seeing how quickly these guys read their vernier calipers is impressive in itself. I'd be taking off my eyeglasses for close work, squinting, finding the best light, and hoping I could find a magnifier.

I agree with you: 'real' vernier calipers are the most rugged of the three types of 'slide caliper'. I've watched a number of youtubes of Pakistani machinists. These guys work on worn or broken parts of heavy construction equipment, farm tractors and heavy truck. Typically, they do build-up welding or joining of broken parts with stickj welding, then remachine the parts. These guys seem to use rules and spring calipers, or vernier calipers. No digital or dial calipers. These guys seem to read their verniers at a quick glance, no magnifiers or eyeglasses needed. Having a vernier caliper is a step up from the use of a rule and spring (or firm joint) calipers.

In the Pakistani shops and working conditions, very nearly everything seems to be patched together as few times over. Other than their cell phones, modern technology is not evident. Wiring for motors on their machine tools is sketchy at best, and welding is done in lathes with no sign of the ground clamp being anywhere in sight. One has to wonder what condition the headstock spindle bearings are in as a result. I do not think a digital or dial vernier would last too long in those shops. These guys use a piece of bent wire on a beat up surface gauge to setup work in 4 jaw chucks, probably because dial indicators were also considered a luxury or would not survive in those conditions. A basic vernier with no scales, no batteries, no rack-and-pinion and gear train, is the ideal thing for these guys.

While some of their repairs leave me wondering as to how long the repaired parts will hold together, I have a great deal of respect for the Pakistani mechanics and machinists. A simple vernier caliper is almost a luxury for those machinists, given what they have to work with. Seeing how quickly these guys read their vernier calipers is impressive in itself. I'd be taking off my eyeglasses for close work, squinting, finding the best light, and hoping I could find a magnifier.

hvnlymachining

Hot Rolled

- Joined

- Jun 21, 2019

- Location

- St.Onge

I have a 36", 60",and 72" vernier caliper. They don't get used often, and didn't cost much, but are very valuable when the need comes around. Like my 36" micrometer, one use will justify the cost or you paid too much!

magneticanomaly

Titanium

- Joined

- Mar 22, 2007

- Location

- On Elk Mountain, West Virginia, USA

I grew up with a 6" spring-lock Helios in my father's shop. Have an 8" Kanon (?) in the shop now that gets used for most measurements that do not require openng the box with the 6-piece set of .0001 Polish mikes, and a Chinese one in the truck toolbox. All vernier, no dials or electronics, and I have taught a couple of my kds to read them. Reading the metric vernier scale on the metric/English one always requires some mental gymnastics

I bought a 24" sliding verner caliper for one job maybe 20 years ago...doubt I have used it since.

I like the ones with the lockable saddle and fine-adjustment screw. Those can be set as accurately as a c-frame mike...allowing for less stiffness as the setting gets larger.

Yes, I now need magnification to read 'em, but 1.5 diopter reading glasses are standard, doubling as safety glasses, in the shop now anyway, and loupes are cheap.

I have never found the absolute accuracy of a measuring tool to be a serious issue, because almost no part fo my business is making parts to a written spec alone. I have to make part A fit part B. Often I insist on having the mating part in my hand, or going to the site to measure myself something too big to move, before I will consent to make a part. The key to that is to use the same tool to measure both, I grinned at Joe M's story about keeping tools and parts warm..SAME TEMPERATURE, too!

I am sure most of us here would enjoy seeing a good photo or two of the OP's caliper...bet he might get an offer, too.

I bought a 24" sliding verner caliper for one job maybe 20 years ago...doubt I have used it since.

I like the ones with the lockable saddle and fine-adjustment screw. Those can be set as accurately as a c-frame mike...allowing for less stiffness as the setting gets larger.

Yes, I now need magnification to read 'em, but 1.5 diopter reading glasses are standard, doubling as safety glasses, in the shop now anyway, and loupes are cheap.

I have never found the absolute accuracy of a measuring tool to be a serious issue, because almost no part fo my business is making parts to a written spec alone. I have to make part A fit part B. Often I insist on having the mating part in my hand, or going to the site to measure myself something too big to move, before I will consent to make a part. The key to that is to use the same tool to measure both, I grinned at Joe M's story about keeping tools and parts warm..SAME TEMPERATURE, too!

I am sure most of us here would enjoy seeing a good photo or two of the OP's caliper...bet he might get an offer, too.

Oh i totallly realize that. The exact reason i joined this forum for some real world info. Thank YouYou need to look at “sold” prices. Anyone can offer unreasonable asking prices.

RC Mech

Stainless

- Joined

- Jul 21, 2014

- Location

- Ontario, Canada

Oh i totallly realize that. The exact reason i joined this forum for some real world info. Thank You

That said if you were local I’d buy them even though I have no immediate need because I’m a tool fiend.

My father was a mechanical engineer and i was going through some of his things as he has passed. Just want to know if and what kind of value this might have. Looked on Ebay and seen similar offered at as much $500+. Thought ,maybe on forum such as this i can find out more information. Thank you

Attachments

Joe Michaels

Diamond

- Joined

- Apr 3, 2004

- Location

- Shandaken, NY, USA

Alan D.

I extend my condolences on the loss of your father. My dad died in 1988, I was 37 years of age, married, 2 kids, and had my degree and Professional Engineer's license and had been in the workforce as an engineer for 16 years and had a good career in progress. Despite all of this I took my Dad's death quite hard and to this day, miss him and miss his wisdom and insight.

Like your late father, I am also a mechanical engineer, though I seem to do more civil engineering in 'retirement' than mechanical engineering. Like your father, I appreciate and accumulate fine tools as well as machine tools and plenty more- welding equipment, blacksmithing, woodworking, rigging, and mechanic's tools.

My children have a respect and appreciation for my life's work, but no real interest in it. Our oldest child is our daughter, age 37, and she is high functioning autistic. She works 5 days a week doing receptionist and clerical work, and lives in a supervised apartment. Our younger child is our son, age 34, a freshly minted lawyer specializing in immigration and labor law. He knows what fine tools are, knows the work I've done, and the responsibilities I took absolutely seriously in my work. Our son is quite happy to ride a 1978 BMW R 100/7 motorcycle, a sister to my own 1978 R 100/7 when he is at home for a visit. He has a box of the 'real' Craftsman mechanic's hand tools and other good US made hand tools like Williams adjustable wrenches, some Proto, some Mac, Mayhew, and even a few odd tools I forged, tempered and machined just so he can use tools his father made. Our son has a deep empathy for working people, and an appreciation of what skilled work entails. Will he want any of my tools and machinery when I am no longer able to use them ? Probably not. He travels light, lives in apartments, and has very different interests and pastimes. He likes to work on his bicycle (don't ask me the specific type, it's a new one with disc brakes and working suspension). He often takes 50-60 mile bicycle rides, downhill skiis in winter, hikes, and is constantly reading and studying and learning and exploring the world's people, political landscapes and much else.

I have 7 long guns and 5 sidearms as well as reloading equipment. Our son knows how to safely handle firearms and has no problem with people hunting for food, or sport shooting. He supports the Second Amendment (talk about someone who knows the US Constitution inside out and upside down). Will he want my firearms and reloading equipment ? He might take my old 'all steel' Model 94 Winchester and my old Ithaca 37 12 gauge shotgun, but chances are the rest will have to be re-homed along with the machine tools, blacksmith shop and machinists' tools. He will get my large Gerstner wooden chest and maybe keep a mike, square and a few odds and ends as keepsakes. Yes, our son knows the name L.S. Starrett and can read a 'real' mike, has been able to since he was about 8 years old and asked to turn all four wheels for a "Pinewood Derby" car (Cubscout project) to the same diameter and good tread flatness. He knows how to rig a load and knows how to use a pinch bar and rollers to move a load, can use a chainsaw, split wood with a maul, and run a tractor. He can drive a manual shift vehicle and prefers it to an automatic except in heavy traffic. He is also a great cook, and has a sandwich and bacon press I made him (milling out 'large profile diamond plate, forged steel handle brackets, and a chunk of cutoff sledge handle for the handle). I am forging him some kitchen knives from truck spring leaf material, making the rivets from scrap stainless and bronze, and scrap micarta for the handle 'scales'.

Us old engineers are a different breed than many people, I think. We take pleasure in making real things, in working accurately, in running as much math in our heads as we can, and on it goes. I tried to instill some of that in our son, and he has at gotten something of a work ethic and sense of what real work is and what responsibility is about. From my wife and her mother, our son got a sense of justice, ethics, and living an upright life. I had some influence in these areas, but I hand the bulk of the credit off to my wife and her late mother.

Our son may never run an engine lathe or mill, though he does like to do a bit of work at the forge. Where and what will become of my tools and machine tools and what-all else is in the hands of my heirs when that time comes. My instruction is simple: call our nephew, who is like another son to me, and is a CNC machinist apprentice, call some of my bros from the area, and let them loose to pick over my shop, office library, and all else. Knowing this will all go (hopefully) into the hands of people who knew me and had some feelings for me and may tell a "Joe Michaels story" or two when they pick up those tools or step up to one of the lathes or mills or grinders is reward beyond the few bucks the tools might fetch at sale. That is the price or value I put on my stuff.

Years ago, a widow who was a friend of one of my bros called him up. Her husband, a Swiss immigrant toolmaker, had died a couple of years previous to that call. He had left his shop, in the 4 car garage of their house, intact, dying suddenly. The couple were childless and apparently had no relatives or anyone else in mind to pass along the contents of the shop to. The widow called some used machinery dealers. These guys came, hemmed, hawed, and offered little and apparently told the widow, who knew nothing about the work and the shop's contents, how little the shop was worth and what trouble it was going to be to move it out and sell it. The widow chased off the dealers and let the shop sit for another year or so, and finally called my bro. She knew he was involved in restoring a steam locomotive and handy with tools. She asked if he was interested in purchasing the contents of her husband's shop in its entirety. She had no idea what was in there, and my bro had a very vague glimpse of it years earlier. My bro said he could pull 4 more of us together, and we'd throw a grand apiece in the pot, totalling 5 grand. Widow said OK. We went down to the widow's place with pickup trucks, rigging equipment and hand tools. We got the doors open and it was Aladdin's Cave. There were:

(1) Bridgeport, variable speed head, 9" x 42" table, fully tooled, X axis power feed

(2) Taiwanese Bridgeport Clones, step cone pulley heads, same as above

(1) 12" Troyke rotary table

(1) Sanford surface grinder

(1) Southbend 'heavy' 10" lathe, taper attachment, long taper spindle

(1) Southbend 10K lathe, fully tooled, scraping crisp on all surfaces

(1) old Craftsman US made floor drill press

(1) Powermatic band saw with gearbox to allow cutting wood and metal

(1) set of steel flat drawers, filled with end mills, horizontal milling machine cutters, twist drills, taper shank drills, taps, dies from 0-80 to over 1" and pipe taps,

Greenlee (old style) tap wrenches and diestocks, drill rod, ground flat stock, hex keys, 'truarc retaining rings' in bulk quantities, dowel pins, socket head screws,

reamers, taper pin reamers, counterbores, and lots more. We had to unload most of the contents to move this set of drawers.

(1) Powermatic carbide tool grinder

granite surface plates, vernier height gauges, dial indicators including Swiss made reading in 0.0001", parallels, micrometers, inside mike sets to 30" diameter,

magnetic bases for indicators, surface gauges, squares (solid head and combination), and lots more. Most of the tools were Starrett, some Brown and Sharpe,

some Mitutoyo

(2) old and not abused US made machinist bench vises (believe 4" or 4 1/2" jaw)

The late Swiss toolmaker had keeled over clearing snow to get to a 'funicular' (a railcar pulled up an incline by a cable). When winter set in, the driveway was impassable with any rubber tired vehicle, maybe with ice chains in 4 WD, but still dicey. The toolmaker, remembering his Swiss heritage, had built a kind of monorail up the side of his driveway and had a 110 volt winch at the head of it to pull the car up. The car had bench seats for two people and a box for groceries or parcels. We knew the loadout of the machine tools had to happen on a dry day. We rented a box truck with lift gate and automatic transmission (A lifesaver backing it up that driveway). We loaded out the machine tools and got them to our homes in about 12 hours flat out.

Hans, to gain US citizenship, had served in the US Army in the 1950's. Somewhere along the line, he'd acquired an M1 Garand rifle. His widow sold it to me as we were about to leave with the load of shop contents. It was made at Springfield Arsenal in August, 1941, all "SA" stamped parts, excellent condition and beautiful bore.

I gave that rifle to another of my bros who had been a USMC gunnery sergeant. 2 tours in Vietnam as a platoon sergeant, scout sniper and tunnel rat (he was one of the smallest Marines the Corps ever had). My bro went thru Boot Camp with the M-1 and was a small arms instructor between tours in Vietnam, so treasures that M1.

Knowing where something like tools, firearms, books and other stuff comes from makes it more special than any dollar value, I think. Treasure your father's tools if you have room for them. I wear my own father's last Carhartt coat on occasion when doing outdoor work. I use woodworking and plumbing tools that were my father's and have his architecture, drafting, and other texts on my shelves. This sort of thing is a tangible link to special people in our lives.

I extend my condolences on the loss of your father. My dad died in 1988, I was 37 years of age, married, 2 kids, and had my degree and Professional Engineer's license and had been in the workforce as an engineer for 16 years and had a good career in progress. Despite all of this I took my Dad's death quite hard and to this day, miss him and miss his wisdom and insight.

Like your late father, I am also a mechanical engineer, though I seem to do more civil engineering in 'retirement' than mechanical engineering. Like your father, I appreciate and accumulate fine tools as well as machine tools and plenty more- welding equipment, blacksmithing, woodworking, rigging, and mechanic's tools.

My children have a respect and appreciation for my life's work, but no real interest in it. Our oldest child is our daughter, age 37, and she is high functioning autistic. She works 5 days a week doing receptionist and clerical work, and lives in a supervised apartment. Our younger child is our son, age 34, a freshly minted lawyer specializing in immigration and labor law. He knows what fine tools are, knows the work I've done, and the responsibilities I took absolutely seriously in my work. Our son is quite happy to ride a 1978 BMW R 100/7 motorcycle, a sister to my own 1978 R 100/7 when he is at home for a visit. He has a box of the 'real' Craftsman mechanic's hand tools and other good US made hand tools like Williams adjustable wrenches, some Proto, some Mac, Mayhew, and even a few odd tools I forged, tempered and machined just so he can use tools his father made. Our son has a deep empathy for working people, and an appreciation of what skilled work entails. Will he want any of my tools and machinery when I am no longer able to use them ? Probably not. He travels light, lives in apartments, and has very different interests and pastimes. He likes to work on his bicycle (don't ask me the specific type, it's a new one with disc brakes and working suspension). He often takes 50-60 mile bicycle rides, downhill skiis in winter, hikes, and is constantly reading and studying and learning and exploring the world's people, political landscapes and much else.

I have 7 long guns and 5 sidearms as well as reloading equipment. Our son knows how to safely handle firearms and has no problem with people hunting for food, or sport shooting. He supports the Second Amendment (talk about someone who knows the US Constitution inside out and upside down). Will he want my firearms and reloading equipment ? He might take my old 'all steel' Model 94 Winchester and my old Ithaca 37 12 gauge shotgun, but chances are the rest will have to be re-homed along with the machine tools, blacksmith shop and machinists' tools. He will get my large Gerstner wooden chest and maybe keep a mike, square and a few odds and ends as keepsakes. Yes, our son knows the name L.S. Starrett and can read a 'real' mike, has been able to since he was about 8 years old and asked to turn all four wheels for a "Pinewood Derby" car (Cubscout project) to the same diameter and good tread flatness. He knows how to rig a load and knows how to use a pinch bar and rollers to move a load, can use a chainsaw, split wood with a maul, and run a tractor. He can drive a manual shift vehicle and prefers it to an automatic except in heavy traffic. He is also a great cook, and has a sandwich and bacon press I made him (milling out 'large profile diamond plate, forged steel handle brackets, and a chunk of cutoff sledge handle for the handle). I am forging him some kitchen knives from truck spring leaf material, making the rivets from scrap stainless and bronze, and scrap micarta for the handle 'scales'.

Us old engineers are a different breed than many people, I think. We take pleasure in making real things, in working accurately, in running as much math in our heads as we can, and on it goes. I tried to instill some of that in our son, and he has at gotten something of a work ethic and sense of what real work is and what responsibility is about. From my wife and her mother, our son got a sense of justice, ethics, and living an upright life. I had some influence in these areas, but I hand the bulk of the credit off to my wife and her late mother.

Our son may never run an engine lathe or mill, though he does like to do a bit of work at the forge. Where and what will become of my tools and machine tools and what-all else is in the hands of my heirs when that time comes. My instruction is simple: call our nephew, who is like another son to me, and is a CNC machinist apprentice, call some of my bros from the area, and let them loose to pick over my shop, office library, and all else. Knowing this will all go (hopefully) into the hands of people who knew me and had some feelings for me and may tell a "Joe Michaels story" or two when they pick up those tools or step up to one of the lathes or mills or grinders is reward beyond the few bucks the tools might fetch at sale. That is the price or value I put on my stuff.

Years ago, a widow who was a friend of one of my bros called him up. Her husband, a Swiss immigrant toolmaker, had died a couple of years previous to that call. He had left his shop, in the 4 car garage of their house, intact, dying suddenly. The couple were childless and apparently had no relatives or anyone else in mind to pass along the contents of the shop to. The widow called some used machinery dealers. These guys came, hemmed, hawed, and offered little and apparently told the widow, who knew nothing about the work and the shop's contents, how little the shop was worth and what trouble it was going to be to move it out and sell it. The widow chased off the dealers and let the shop sit for another year or so, and finally called my bro. She knew he was involved in restoring a steam locomotive and handy with tools. She asked if he was interested in purchasing the contents of her husband's shop in its entirety. She had no idea what was in there, and my bro had a very vague glimpse of it years earlier. My bro said he could pull 4 more of us together, and we'd throw a grand apiece in the pot, totalling 5 grand. Widow said OK. We went down to the widow's place with pickup trucks, rigging equipment and hand tools. We got the doors open and it was Aladdin's Cave. There were:

(1) Bridgeport, variable speed head, 9" x 42" table, fully tooled, X axis power feed

(2) Taiwanese Bridgeport Clones, step cone pulley heads, same as above

(1) 12" Troyke rotary table

(1) Sanford surface grinder

(1) Southbend 'heavy' 10" lathe, taper attachment, long taper spindle

(1) Southbend 10K lathe, fully tooled, scraping crisp on all surfaces

(1) old Craftsman US made floor drill press

(1) Powermatic band saw with gearbox to allow cutting wood and metal

(1) set of steel flat drawers, filled with end mills, horizontal milling machine cutters, twist drills, taper shank drills, taps, dies from 0-80 to over 1" and pipe taps,

Greenlee (old style) tap wrenches and diestocks, drill rod, ground flat stock, hex keys, 'truarc retaining rings' in bulk quantities, dowel pins, socket head screws,

reamers, taper pin reamers, counterbores, and lots more. We had to unload most of the contents to move this set of drawers.

(1) Powermatic carbide tool grinder

granite surface plates, vernier height gauges, dial indicators including Swiss made reading in 0.0001", parallels, micrometers, inside mike sets to 30" diameter,

magnetic bases for indicators, surface gauges, squares (solid head and combination), and lots more. Most of the tools were Starrett, some Brown and Sharpe,

some Mitutoyo

(2) old and not abused US made machinist bench vises (believe 4" or 4 1/2" jaw)

The late Swiss toolmaker had keeled over clearing snow to get to a 'funicular' (a railcar pulled up an incline by a cable). When winter set in, the driveway was impassable with any rubber tired vehicle, maybe with ice chains in 4 WD, but still dicey. The toolmaker, remembering his Swiss heritage, had built a kind of monorail up the side of his driveway and had a 110 volt winch at the head of it to pull the car up. The car had bench seats for two people and a box for groceries or parcels. We knew the loadout of the machine tools had to happen on a dry day. We rented a box truck with lift gate and automatic transmission (A lifesaver backing it up that driveway). We loaded out the machine tools and got them to our homes in about 12 hours flat out.

Hans, to gain US citizenship, had served in the US Army in the 1950's. Somewhere along the line, he'd acquired an M1 Garand rifle. His widow sold it to me as we were about to leave with the load of shop contents. It was made at Springfield Arsenal in August, 1941, all "SA" stamped parts, excellent condition and beautiful bore.

I gave that rifle to another of my bros who had been a USMC gunnery sergeant. 2 tours in Vietnam as a platoon sergeant, scout sniper and tunnel rat (he was one of the smallest Marines the Corps ever had). My bro went thru Boot Camp with the M-1 and was a small arms instructor between tours in Vietnam, so treasures that M1.

Knowing where something like tools, firearms, books and other stuff comes from makes it more special than any dollar value, I think. Treasure your father's tools if you have room for them. I wear my own father's last Carhartt coat on occasion when doing outdoor work. I use woodworking and plumbing tools that were my father's and have his architecture, drafting, and other texts on my shelves. This sort of thing is a tangible link to special people in our lives.

Eric M

Cast Iron

- Joined

- Nov 21, 2007

- Location

- Orlando, FL

I NEVER get tired of reading Joe Michaels' writings. He absolutely paints a picture with words.Alan D.

I extend my condolences on the loss of your father. My dad died in 1988, I was 37 years of age, married, 2 kids, and had my degree and Professional Engineer's license and had been in the workforce as an engineer for 16 years and had a good career in progress. Despite all of this I took my Dad's death quite hard and to this day, miss him and miss his wisdom and insight.

Like your late father, I am also a mechanical engineer, though I seem to do more civil engineering in 'retirement' than mechanical engineering. Like your father, I appreciate and accumulate fine tools as well as machine tools and plenty more- welding equipment, blacksmithing, woodworking, rigging, and mechanic's tools.

My children have a respect and appreciation for my life's work, but no real interest in it. Our oldest child is our daughter, age 37, and she is high functioning autistic. She works 5 days a week doing receptionist and clerical work, and lives in a supervised apartment. Our younger child is our son, age 34, a freshly minted lawyer specializing in immigration and labor law. He knows what fine tools are, knows the work I've done, and the responsibilities I took absolutely seriously in my work. Our son is quite happy to ride a 1978 BMW R 100/7 motorcycle, a sister to my own 1978 R 100/7 when he is at home for a visit. He has a box of the 'real' Craftsman mechanic's hand tools and other good US made hand tools like Williams adjustable wrenches, some Proto, some Mac, Mayhew, and even a few odd tools I forged, tempered and machined just so he can use tools his father made. Our son has a deep empathy for working people, and an appreciation of what skilled work entails. Will he want any of my tools and machinery when I am no longer able to use them ? Probably not. He travels light, lives in apartments, and has very different interests and pastimes. He likes to work on his bicycle (don't ask me the specific type, it's a new one with disc brakes and working suspension). He often takes 50-60 mile bicycle rides, downhill skiis in winter, hikes, and is constantly reading and studying and learning and exploring the world's people, political landscapes and much else.

I have 7 long guns and 5 sidearms as well as reloading equipment. Our son knows how to safely handle firearms and has no problem with people hunting for food, or sport shooting. He supports the Second Amendment (talk about someone who knows the US Constitution inside out and upside down). Will he want my firearms and reloading equipment ? He might take my old 'all steel' Model 94 Winchester and my old Ithaca 37 12 gauge shotgun, but chances are the rest will have to be re-homed along with the machine tools, blacksmith shop and machinists' tools. He will get my large Gerstner wooden chest and maybe keep a mike, square and a few odds and ends as keepsakes. Yes, our son knows the name L.S. Starrett and can read a 'real' mike, has been able to since he was about 8 years old and asked to turn all four wheels for a "Pinewood Derby" car (Cubscout project) to the same diameter and good tread flatness. He knows how to rig a load and knows how to use a pinch bar and rollers to move a load, can use a chainsaw, split wood with a maul, and run a tractor. He can drive a manual shift vehicle and prefers it to an automatic except in heavy traffic. He is also a great cook, and has a sandwich and bacon press I made him (milling out 'large profile diamond plate, forged steel handle brackets, and a chunk of cutoff sledge handle for the handle). I am forging him some kitchen knives from truck spring leaf material, making the rivets from scrap stainless and bronze, and scrap micarta for the handle 'scales'.

Us old engineers are a different breed than many people, I think. We take pleasure in making real things, in working accurately, in running as much math in our heads as we can, and on it goes. I tried to instill some of that in our son, and he has at gotten something of a work ethic and sense of what real work is and what responsibility is about. From my wife and her mother, our son got a sense of justice, ethics, and living an upright life. I had some influence in these areas, but I hand the bulk of the credit off to my wife and her late mother.

Our son may never run an engine lathe or mill, though he does like to do a bit of work at the forge. Where and what will become of my tools and machine tools and what-all else is in the hands of my heirs when that time comes. My instruction is simple: call our nephew, who is like another son to me, and is a CNC machinist apprentice, call some of my bros from the area, and let them loose to pick over my shop, office library, and all else. Knowing this will all go (hopefully) into the hands of people who knew me and had some feelings for me and may tell a "Joe Michaels story" or two when they pick up those tools or step up to one of the lathes or mills or grinders is reward beyond the few bucks the tools might fetch at sale. That is the price or value I put on my stuff.

Years ago, a widow who was a friend of one of my bros called him up. Her husband, a Swiss immigrant toolmaker, had died a couple of years previous to that call. He had left his shop, in the 4 car garage of their house, intact, dying suddenly. The couple were childless and apparently had no relatives or anyone else in mind to pass along the contents of the shop to. The widow called some used machinery dealers. These guys came, hemmed, hawed, and offered little and apparently told the widow, who knew nothing about the work and the shop's contents, how little the shop was worth and what trouble it was going to be to move it out and sell it. The widow chased off the dealers and let the shop sit for another year or so, and finally called my bro. She knew he was involved in restoring a steam locomotive and handy with tools. She asked if he was interested in purchasing the contents of her husband's shop in its entirety. She had no idea what was in there, and my bro had a very vague glimpse of it years earlier. My bro said he could pull 4 more of us together, and we'd throw a grand apiece in the pot, totalling 5 grand. Widow said OK. We went down to the widow's place with pickup trucks, rigging equipment and hand tools. We got the doors open and it was Aladdin's Cave. There were:

(1) Bridgeport, variable speed head, 9" x 42" table, fully tooled, X axis power feed

(2) Taiwanese Bridgeport Clones, step cone pulley heads, same as above

(1) 12" Troyke rotary table

(1) Sanford surface grinder

(1) Southbend 'heavy' 10" lathe, taper attachment, long taper spindle

(1) Southbend 10K lathe, fully tooled, scraping crisp on all surfaces

(1) old Craftsman US made floor drill press

(1) Powermatic band saw with gearbox to allow cutting wood and metal

(1) set of steel flat drawers, filled with end mills, horizontal milling machine cutters, twist drills, taper shank drills, taps, dies from 0-80 to over 1" and pipe taps,

Greenlee (old style) tap wrenches and diestocks, drill rod, ground flat stock, hex keys, 'truarc retaining rings' in bulk quantities, dowel pins, socket head screws,

reamers, taper pin reamers, counterbores, and lots more. We had to unload most of the contents to move this set of drawers.

(1) Powermatic carbide tool grinder

granite surface plates, vernier height gauges, dial indicators including Swiss made reading in 0.0001", parallels, micrometers, inside mike sets to 30" diameter,

magnetic bases for indicators, surface gauges, squares (solid head and combination), and lots more. Most of the tools were Starrett, some Brown and Sharpe,

some Mitutoyo

(2) old and not abused US made machinist bench vises (believe 4" or 4 1/2" jaw)

The late Swiss toolmaker had keeled over clearing snow to get to a 'funicular' (a railcar pulled up an incline by a cable). When winter set in, the driveway was impassable with any rubber tired vehicle, maybe with ice chains in 4 WD, but still dicey. The toolmaker, remembering his Swiss heritage, had built a kind of monorail up the side of his driveway and had a 110 volt winch at the head of it to pull the car up. The car had bench seats for two people and a box for groceries or parcels. We knew the loadout of the machine tools had to happen on a dry day. We rented a box truck with lift gate and automatic transmission (A lifesaver backing it up that driveway). We loaded out the machine tools and got them to our homes in about 12 hours flat out.

Hans, to gain US citizenship, had served in the US Army in the 1950's. Somewhere along the line, he'd acquired an M1 Garand rifle. His widow sold it to me as we were about to leave with the load of shop contents. It was made at Springfield Arsenal in August, 1941, all "SA" stamped parts, excellent condition and beautiful bore.

I gave that rifle to another of my bros who had been a USMC gunnery sergeant. 2 tours in Vietnam as a platoon sergeant, scout sniper and tunnel rat (he was one of the smallest Marines the Corps ever had). My bro went thru Boot Camp with the M-1 and was a small arms instructor between tours in Vietnam, so treasures that M1.

Knowing where something like tools, firearms, books and other stuff comes from makes it more special than any dollar value, I think. Treasure your father's tools if you have room for them. I wear my own father's last Carhartt coat on occasion when doing outdoor work. I use woodworking and plumbing tools that were my father's and have his architecture, drafting, and other texts on my shelves. This sort of thing is a tangible link to special people in our lives.

L Vanice

Diamond

- Joined

- Feb 8, 2006

- Location

- Fort Wayne, IN

The excellent photos in post #17 show that the main scale stops at 42.5 inches and the vernier scale is 2.45 inches long. That means that the maximum outside capacity of the caliper is 40 inches. The caliper was made in Germany, so this size caliper would likely mostly be sold with a 1 meter capacity and metric scale. I suspect the 40 inch version was made to take advantage of the popularity of the 1 meter version and avoid making a special length of long caliper frame for the inch market.

Larry

Larry

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 17

- Views

- 3K

- Replies

- 1

- Views

- 1K

- Replies

- 7

- Views

- 4K