BugRobotics

Stainless

- Joined

- Jun 22, 2015

- Location

- Denver, CO

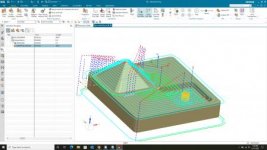

Yea I don't use it either. Looks like the CAMWorks is more efficient as it doesn't helix in and just plows material off in that one plane. I don't have an option to not helix into that area which would be nice.If I enable both ways it drops it down to 2.85 (2:51)

I tried both ways once, when they first released it and didn't like it at all

View attachment 349239