How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Doosan/Fanuc user, with a bunch of controller questions

- Thread starter ngng

- Start date

- Replies 27

- Views 2,773

DouglasJRizzo

Titanium

- Joined

- Jun 7, 2011

- Location

- Ramsey, NJ.

When using G28, use incremental mode (G91) on the same line. So, to home the Z without going down to the table first, write "G28 G91 Z0" and the Z will go to home position without heading down first. Same for other axii.FINALLY figured out how to reset the tool setter if it aborts or fails. Put together a short video, will link it once it's uploaded.

To answer my previous question about length only toolsetting. My operation was failing because of another previously failed probe op where it couldn't find the surface. I was able to provide the facemill length correctly today.

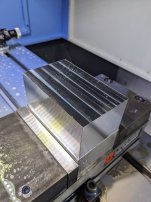

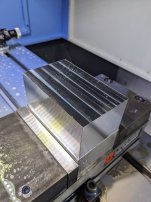

View attachment 389364

View attachment 389363

Also found another odd behiavor...G28 X0 Y0 Z0 sends the table to the machine home. It also sends the spindle to the table...??

Both the G53 and G28 G91 worked today. Struggled a bit trying to figure out how to load from USB but was able to get it sorted. Looked into the advanced probing menu but there's a ton of stuff that I have no idea what it does lol

Was able to write my warmup program. Turns out this machine does not like decimal places with the P value. Made some actual chips as well! Was trying out a generic Haas post from both Surfcam and Mastercam. Mastercam ran fine, but Surfcam threw an "Illegal plane select" alarm. My suspicion is that the Surfcam post includes I J K R with the interpolation modal.

Was able to write my warmup program. Turns out this machine does not like decimal places with the P value. Made some actual chips as well! Was trying out a generic Haas post from both Surfcam and Mastercam. Mastercam ran fine, but Surfcam threw an "Illegal plane select" alarm. My suspicion is that the Surfcam post includes I J K R with the interpolation modal.

Feeling a lot better today. Able to probe, set tools, load programs, edit program, and actually cut!I felt the same way for a while when I started on Fanuc then it becomes second nature. You'll get there as you use it more but it will always be inconvenient compared to Haas or others.. The thing with Fanuc that's just something to expect is lots of button presses. I'm constantly surprised by how many button presses it takes to do simple tasks. It's a regular game of navigating through tabs and menus.

I ran into this a few times today and it looks like pressing EDIT, then RESET resolved the issue.This sounds like some kind of bug that you should talk to the distributor about. The iHMI controls are still a little rough around the edges so there might be some software updates to remedy this. There was an update a few months ago to fix some issues with FTP file access and other minor inconsistencies.

I hit feed hold and then pressed the spindle off (red button) but it didn't appear to do anything. I will look into the params and see if there is an option to turn this off. What does MTB stand for?MTBs will set this functionality up differently so it's hard to say. Typically if you start the spindle in manual mode after programming a speed in MDI, this should stop it.

So I was not able to reproduce the issue today. We loaded both with and without the NC extension.I think the Fanuc NC programs need to be without an extension. This is at least the case on older Fanuc machines. I can't remember if it's that way on the iHMI generation of controls. This also might not be the problem you're describing.

Vancbiker

Diamond

- Joined

- Jan 5, 2014

- Location

- Vancouver, WA. USA

........I hit feed hold and then pressed the spindle off (red button) but it didn't appear to do anything. I will look into the params and see if there is an option to turn this off. What does MTB stand for?.......

After you press feedhold, switch to a manual mode like Handle or Jog. Then press the spindle off button. The spindle will probably stop. This behavior is determined by how the MTB (Machine Tool Builder) has integrated the control to their machine. Most do it as described above, but not all.

Thank you! Will give this a try.After you press feedhold, switch to a manual mode like Handle or Jog. Then press the spindle off button. The spindle will probably stop. This behavior is determined by how the MTB (Machine Tool Builder) has integrated the control to their machine. Most do it as described above, but not all.

PracticalAE

Plastic

- Joined

- Jun 13, 2022

- Location

- Ohio

Similar threads

- Replies

- 24

- Views

- 1K

- Replies

- 10

- Views

- 984