Hello.

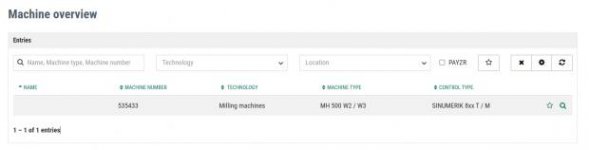

I got myself a MAHO 500W CNC. After all this time working with converted chinese mills and cnc routers,

owning a proper machine for the first time feels nice.

To the subject, I would like to ask if anybody has any material/documents to share regarding this machine.

Additionally, since I have never worked with 40 tapers and drawbars yet (I have the R8-TTS tooling on my small chinese mill),

what type of drawbar does this machine have? I can see the engravings on the pulling jaws

Horizontal: I 35 013 and II 35 013

Vertical: I 35 595 and II 35 595

Do these codes help identifying the drawbar and the pull stud to use?

The cone is 40 taper.

Thanks a ton.

I got myself a MAHO 500W CNC. After all this time working with converted chinese mills and cnc routers,

owning a proper machine for the first time feels nice.

To the subject, I would like to ask if anybody has any material/documents to share regarding this machine.

Additionally, since I have never worked with 40 tapers and drawbars yet (I have the R8-TTS tooling on my small chinese mill),

what type of drawbar does this machine have? I can see the engravings on the pulling jaws

Horizontal: I 35 013 and II 35 013

Vertical: I 35 595 and II 35 595

Do these codes help identifying the drawbar and the pull stud to use?

The cone is 40 taper.

Thanks a ton.