How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Philips, Grundig, Millplus Information Collaboration

- Thread starter Nerv

- Start date

- Replies 152

- Views 33,879

Hello, I'm sorry I entered the wrong email address here is the correct one: [email protected] . Sorry again.

Can you please send me the download link, think it should work for my DMU70V.

I have sent you PM.

Hello, I want to ask where the link would be sent. I haven't received it yet, please send it again. [email protected]

Thanks.

Thanks.

Regards to all

I need help with my machine DMU 80P, year 1999. MILL PLUS nc unit with simodrive 611. I have a B74 error on the DDC 2 card. It was tested by replacing it with another card and the alarm moved to another axis. Is it possible to move the B axis with parameters and cables to another channel, since the fifth axis is not mounted on the machine?

Thanks

[email protected]

I need help with my machine DMU 80P, year 1999. MILL PLUS nc unit with simodrive 611. I have a B74 error on the DDC 2 card. It was tested by replacing it with another card and the alarm moved to another axis. Is it possible to move the B axis with parameters and cables to another channel, since the fifth axis is not mounted on the machine?

Thanks

[email protected]

On the DMU 5V MillPlus 1996 machine (5-axes), an error O 208 pops up after loading. Probably the information on the hard disk is damaged . I ask for help. [email protected]

Attachments

Ihave send you email with my hard drive image it is V4.00 MillPlus from my DMU50evoOn the DMU 5V MillPlus 1996 machine (5-axes), an error O 208 pops up after loading. Probably the information on the hard disk is damaged . I ask for help. [email protected]

در دستگاه DMU 5V MillPlus 1996 (5 محور)، خطای O 208 پس از بارگیری ظاهر می شود. احتمالا اطلاعات هارد دیسک آسیب دیده است. من کمک می خواهم. [email protected]

Hi slava.

I think you should contact the professional team that runs https://www.pgh-controlparts.com.

Be with them, I also had a big problem with the Philips controller which was fixed with the site instructions.

have one Deckel DMU 80 with MillPlus in my shop. I reload parameters after a BIOS battery problem and now the machine is up and running, but when I try to start spindle M3 S1000 it gives this error: E102 prog. “S”˃ max. diameter of tool

Machine accept only maximum 18 rpm for the spindle.

My machine doesn’t have any tool changer and there is no reference for speed on tool table or some sort of setting.

I don't have manual or any error list to check what is the meaning of this error.

Do you think you can help with any advice?

Thank you,

Machine accept only maximum 18 rpm for the spindle.

My machine doesn’t have any tool changer and there is no reference for speed on tool table or some sort of setting.

I don't have manual or any error list to check what is the meaning of this error.

Do you think you can help with any advice?

Thank you,

gordankrota

Plastic

- Joined

- Sep 18, 2022

HI, happy new year to all! i have problem with dmu50v, we bought maschine with software v420 but configuration of the maschine is y axis as main axis-, so y and z axis are switched. when y switch on control board is pressed on screen is correct but z axis move whichever configuration we try stay the same, shud we install new software or is possible otherwise. or some other maschine back up. thanks for help!

markp

Hot Rolled

- Joined

- Oct 7, 2006

- Location

- Petaluma CA 94952

I was having problems with my 2000 DMU50V with Millplus 4.0. X53, X04, Z04, and other errors related to the E stop chain usually when opening or closing the door. I received some advice from another member and replaced some of the Estop relays in the cabinet and some of the relays on the DDC boards. That helped a bit and I was able to make parts but occasionally still had to stop and restart to keep the machine going. A few weeks ago, the control stopped at boot with an M71 error (no power to PG1220). Tried to restart but the screen was blank, no power on the PG1220. Power supply for the PG1220 was dead. I did see evidence that at some point, the 5 mosfets were replaced along with a few other components. Ive had the machine since 2015 so it was sometime before that.

Power supply is a Philips PE1927/71. Looked on ebay and there were a couple used units in Europe and Indonesia for $1400 or more. I searched around a bit and saw an identical power supply designated as a PE 1927/23B. It was only 69$ so I bought both that the seller had for sale. I looked it over upon arrival with an electrical engineer buddy of mine and he confirmed it was the same except for the voltage input jumper, which was set to 120VAC on the $69 PS. Installed it, checked the voltage outputs on the test points of the PG1220, and so far Ive had no errors at all after making a few parts. Might be helpful to know as it seems like a common problem with these older DMG machines. Im sure it was just the fets that were bad but it worked out in the end.

If anyone has a schematic for these supplies Id like to get a copy. I searched far and wide and didn't see anything online. Philips sold their PS division to Cherokee at some point, and Cherokee merged with another company so its probably all lost.

Power supply is a Philips PE1927/71. Looked on ebay and there were a couple used units in Europe and Indonesia for $1400 or more. I searched around a bit and saw an identical power supply designated as a PE 1927/23B. It was only 69$ so I bought both that the seller had for sale. I looked it over upon arrival with an electrical engineer buddy of mine and he confirmed it was the same except for the voltage input jumper, which was set to 120VAC on the $69 PS. Installed it, checked the voltage outputs on the test points of the PG1220, and so far Ive had no errors at all after making a few parts. Might be helpful to know as it seems like a common problem with these older DMG machines. Im sure it was just the fets that were bad but it worked out in the end.

If anyone has a schematic for these supplies Id like to get a copy. I searched far and wide and didn't see anything online. Philips sold their PS division to Cherokee at some point, and Cherokee merged with another company so its probably all lost.

pgh-team

Plastic

- Joined

- Mar 9, 2022

- Location

- Leipzig, Germany

The problem with the PE1927/xx power supply is a well known problem. The 1927 etc. P/S components have reached their end of life and are VERY DANGEROUS still to be used in the control. The Mill Plus has no over temperature protection, so if the P/S overheats, IT WILL JUST BLOW UP AND BURNING HALF THE CONTROL MODULES. We had several customers, which had the P/S repaired by some local shop, only to having it fail a few month later, taking half the control with it. Sometimes we could repair it, if we had the parts, but the bill was exceeding Euro 15000. The alternative was to scrap the machine .So please be sure you know what you are doing. We at ROBTEC don't even test the repair-controls with this P/S at all, but replace it with a new one.

gordankrota

Plastic

- Joined

- Sep 18, 2022

PLEASE ANY HELP,THANKSHI, happy new year to all! i have problem with dmu50v, we bought maschine with software v420 but configuration of the maschine is y axis as main axis-, so y and z axis are switched. when y switch on control board is pressed on screen is correct but z axis move whichever configuration we try stay the same, shud we install new software or is possible otherwise. or some other maschine back up. thanks for help!

gordankrota

Plastic

- Joined

- Sep 18, 2022

I do have a full set of backup discs for Millplus V4.0 for my DMU50v. Ive copied these in case anyone needs digital versions to rebuild after a trashed drive on the same machine. Pretty sure all youd have to insert your machines parameters into the flies to replace my shipped parameters.

gordankrota

Plastic

- Joined

- Sep 18, 2022

hi markp, i have v420 dmu50v coud you share back up on [email protected], thanks

Hi!Thanks

I have the BIOS re-entered.

The machine boots up but when it comes to the machine screen I get alarm for "parameters missing", then it reboots again.

I have read that the BIOS battery also holds a SRAM memory with start up parameters and the only way to get them back in is to reinstall the software.

Translated from a french forum, I have read about same solution in industryarena.

Machine finally repaired!!!! WOW!!!

The problem was that having emptied the EPC-8 card of its memory, the machine parameters went completely to the strawberries. Impossible to be able to put them back in a normal way because they are stored on an SRAM memory integrated into the card itself. It was necessary to go through the machine installation software (provided with the machine on diskette) which works only on a PC running under DOS.

I´m having the exact same problem but i didnt get the diskette with the machine. Can you please send me the files by email? alex @ schermansab . se

I dont have the diskettes either, I pasted the answer from an old french forum.Hi!

I´m having the exact same problem but i didnt get the diskette with the machine. Can you please send me the files by email? alex @ schermansab . se

I finally solved this thanks to drimjohns mirror image disc, great thanks! In the service menu with that disc I was able to

"load default parameters". With my v331 disc that was not possible.

Hi! And thanks for replying!I dont have the diskettes either, I pasted the answer from an old french forum.

I finally solved this thanks to drimjohns mirror image disc, great thanks! In the service menu with that disc I was able to

"load default parameters". With my v331 disc that was not possible.

But did you get in to your operating system before you solved this?

My machine is a MASTURN CNC 50, Teach-in lathe.

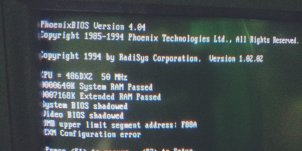

My problem is that the system doesn’t find the operating system. (See pictures)

I bought this machine not working. The guy I bought from told me they just removed the incoming power, changed the position and then connected the power and the machine didn’t find its references (or something like that)

When I finally got the machine home I found an exploded/broken capacitor named A5 (Card pos C106) I changed it and put it all together. Not perfectly because it was a crater after the explosion so I found another connecting point little bit beside. (See picture)

I also checked the voltage on the BIOS battery and it’s was about 2V so I changed it by just replaced it without connecting any other power source… so now I’m standing here with no values to but in the BIOS configuration..

I’ve tried a lot of different combinations and now all the checkpoints in the startup-display seems to be ok but it doesn’t find the operating system.

I may have something missing in the BIOS configuration.. can anyone kind person help me please?

The pictures was too large so I will try to post by shared link.

Dear markpI do have a full set of backup discs for Millplus V4.0 for my DMU50v. Ive copied these in case anyone needs digital versions to rebuild after a trashed drive on the same machine. Pretty sure all youd have to insert your machines parameters into the flies to replace my shipped parameters.

I have a DMU 50V from 1996, with Philips PG1220 Series, Grundig Millplus control.I ask you very much to send an image of the hard disk and foto bios. The machine is 5-axis, I send you: photo of errors (foto error bios.jpg, foto error PO.jpg), photo of HDD (foto hdd PO.jpg, foto hdd.jpg, foto hdd2.jpg), photo of CNC and machine ( foto CNC.jpg, foto stanok.jpg).

My e-mail: [email protected]

Thank you so much.

Attachments

Уважаемый abelcncВсем привет,

Размещая документацию моего dmu50, я нашел способ выполнить кинематику в MillPlus, Heidenhain и Siemens. Отсканировал, если кому нужно могу поделиться.

У меня есть DMU 50V 1996 года, Philips PG1220 Series, управление Grundig Millplus. На эту машину утерян весь комплект документации, кроме электрических схем.

Пожалуйста, поделитесь документацией.

Моя электронная почта: [email protected]

Большое спасибо.

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 3

- Views

- 198

- Replies

- 1

- Views

- 829

- Replies

- 6

- Views

- 170

- Replies

- 0

- Views

- 72