michiganbuck

Diamond

- Joined

- Jun 28, 2012

- Location

- Mt Clemens, Michigan 48035

There would likely be a market for simple greased heavy-duty bearings,

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Joe, The 1/2" plate has a hole bored through. and the 2-1/2" bar slips through and is welded both sides. Didn't have quite enough of the solid bar so a piece of schedule 40 was slipped over it to reach the first "long" frame member.The picture on the right also bothers me. I'd fear that the garter weld will fail from shock twisting. A second plate welded to both cross-beam and pivot shaft should prevent that.

A wax-impregnated wooden bearing seat should work, and would not be at all fussy about alignment or dirt. One could do the alignment with a laser beam or two and some paper.

One can buy rock maple bearings of this kind, such as Woodex.

https://woodexbearing.com/

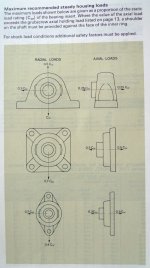

Robert,The pillow block housings are made with ductile cast iron. It will have a tensile strength of 60,000 psi. The bearing housing side walls are .25 inch thick and 1.5 inches wide. The tensile strength of the bearing housing with a static load would be 2 sides x 1.5" x .25" x 60,000 psi =45,000 pounds.

The load on the bearing is the sum of the static load of 8,000 pounds plus the rate of change of the momentum of the truck as it drives on to the ramp. The second ( moving) load is determined by the trucks speed and the angle of the ramp. If the ramp and the approach driveway are both level and at the same height and if the truck is not accelerating or braking as it approaches the ramp the moving load would be zero.

The over load condition was caused by one of the following:

A very large impact load which exceeded the ductile cast iron's Charpy impact strength.

A very large dynamic load caused by the truck accelerating up a ramp.

A misaligned shaft in the bearing.

Keep in mind that the shaft is 12 inches (?) long and the bearing housing is only 1.5 inches wide. A 1000 pound load at the far end of the shaft would produce a bearing housing load of 7000 pounds if the shaft pivots on the inside edge of the bearing. This is why a stiff platform design is important.

So I'm not clear where this very powerful lifting force at the bearing is coming from.

Must be an awful lot of G to generate the forces Robert is talking about.The 1100 lb half of the teeter totter that is going up as the vehicle slams down into the stop could have something to do with it.

I mean, I probably don't care, but are you blowing smoke here? Or were you possible more in electrical or software? I only ask because I needed about 5min with my calculator to figure out the inertia problems. The fact that you "missed" the uplift components means nothing was calculated. That could not be missed.I'm a retired engineer and worked with a good friend who's a retired mechanical design engineer. We didn't do many detailed design calculations, other than the obvious beam calcs. We used our judgement, based on several years combined experience, and tried to go big.

Yes we missed the uplift forces, that destroyed the bearing housing.

I'm open to constructive comment, and appreciate the discussion here.

The vehicle speeds, and number of cycles per day are quite low, so we have confidence.

We'll go for a simple robust solution to the bearing issue, and see what else we can do to take some of the shock loading out by adding bumpstops.

I'll keep y'all informed.

Thanks again.

Bob

According to motion, that is not occurring.There is a optimum location for the shock absorber along the length of the rotating beam to eliminate the up lift force on the bearing when the beam tilts down. It is called the center of percussion.

Center of percussion - Wikipedia

en.wikipedia.org

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.