For the grinding, I am working on a custom adapter so I can use my NSK Planet 600 with the fine grinding head.

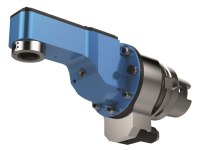

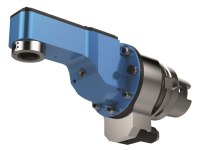

I do have the corner milling attachment and the angle milling head, BUT they are in storage, what I actually use are Benz-Tools SLIM WGZ angle head, and the Benz-Tools FLEX WDX angle head, vastly superior solutions and they have integrated DIN69871 tapers which go right into my spindle. See photos here:

I do have the corner milling attachment and the angle milling head, BUT they are in storage, what I actually use are Benz-Tools SLIM WGZ angle head, and the Benz-Tools FLEX WDX angle head, vastly superior solutions and they have integrated DIN69871 tapers which go right into my spindle. See photos here: