Hi everyone!

I own a 1999 Deckel Maho DMU60P (5axis table/table).

I have a problem with the table. Table moves freely 0.25mm, this also manifests itself during processing, most often during drilling, and I can also move it with my hands (I will attach a video).

At the same time, the axis of rotation and tilt work properly, but due to the backlash, it is almost impossible to process parts.

Perhaps it is necessary to dismantle the table, if so

I have a question about dismantling the table to know how it is done in case of some kind of incident.

If someone had experience in removing this kind of tables, tell me if there are any nuances in dismantling.

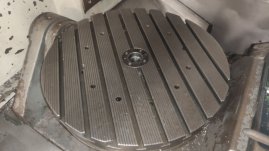

If I unscrew 12 bolts in a circle and 4 in the center and carefully lift the table (I will attach a photo), will I be able to lift it without damaging anything inside the table. It's interesting to hear how it's done.

Perhaps someone has drawings or a technical manual for these machines. It would be useful for me too.

I will be glad for any help.

Thank you in advance!

I own a 1999 Deckel Maho DMU60P (5axis table/table).

I have a problem with the table. Table moves freely 0.25mm, this also manifests itself during processing, most often during drilling, and I can also move it with my hands (I will attach a video).

At the same time, the axis of rotation and tilt work properly, but due to the backlash, it is almost impossible to process parts.

Perhaps it is necessary to dismantle the table, if so

I have a question about dismantling the table to know how it is done in case of some kind of incident.

If someone had experience in removing this kind of tables, tell me if there are any nuances in dismantling.

If I unscrew 12 bolts in a circle and 4 in the center and carefully lift the table (I will attach a photo), will I be able to lift it without damaging anything inside the table. It's interesting to hear how it's done.

Perhaps someone has drawings or a technical manual for these machines. It would be useful for me too.

I will be glad for any help.

Thank you in advance!