Sage Brush

Plastic

- Joined

- Jan 31, 2023

- Location

- Waco, Texas, USA

Hello,

I have a Leadwell MCV-OP with a carousel tool changer and Fanuc OM control. One of those "running when pulled from service" machines. It runs a program ok but will not change tools. I think I have found the problem but not sure. Let's say I try to change a tool in MDI mode:

G91 G28 Z0; (send Z axis home)

T2 M6; (call new tool, tool change)

When I run this, the spindle goes up to home, then orients, and then the control hangs with the curser blinking on the M6 line. A diagnostic screen says the control is waiting for an M code to finish. By the way, I think the tool change process is controlled by the logic ladder. I don't see a program like O9001 and per the machine manual, there seem to be no parameters set to call a tool change program or macro.

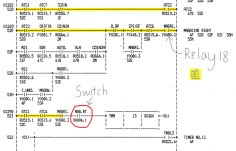

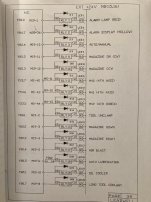

I thought maybe an air solenoid was stuck, but then I noticed there were no relay LEDs on in the back of the machine. Looking at the logic ladder on the control, I see a rung for "Magazine Right". Seems like the next step would indeed be moving the carousel over to grab the tool. Its output (Y0080.3) turns on when I try a tool change. The next rung down is now almost "on", except it's waiting for a signal that the carousel has actually moved. Looking in the manual, I see that relay 16 is connected to an output also called Y0080.3. This same relay powers the air solenoid that moves the carousel left or right. Seems to me that the logic ladder is trying to turn on relay 16 and move the carousel over, but there must be a bad connection or something between the control and the relay. Or is it more complicated than that?

Just as a side note, I can run M26 (Tool Unclamp) and the spindle does unclamp and a relay clicks in the back of the machine. So at least that relay works. Also tried M21 (Magazine Right). The control hangs in exactly the same way as above.

Thanks,

Sage Brush

I have a Leadwell MCV-OP with a carousel tool changer and Fanuc OM control. One of those "running when pulled from service" machines. It runs a program ok but will not change tools. I think I have found the problem but not sure. Let's say I try to change a tool in MDI mode:

G91 G28 Z0; (send Z axis home)

T2 M6; (call new tool, tool change)

When I run this, the spindle goes up to home, then orients, and then the control hangs with the curser blinking on the M6 line. A diagnostic screen says the control is waiting for an M code to finish. By the way, I think the tool change process is controlled by the logic ladder. I don't see a program like O9001 and per the machine manual, there seem to be no parameters set to call a tool change program or macro.

I thought maybe an air solenoid was stuck, but then I noticed there were no relay LEDs on in the back of the machine. Looking at the logic ladder on the control, I see a rung for "Magazine Right". Seems like the next step would indeed be moving the carousel over to grab the tool. Its output (Y0080.3) turns on when I try a tool change. The next rung down is now almost "on", except it's waiting for a signal that the carousel has actually moved. Looking in the manual, I see that relay 16 is connected to an output also called Y0080.3. This same relay powers the air solenoid that moves the carousel left or right. Seems to me that the logic ladder is trying to turn on relay 16 and move the carousel over, but there must be a bad connection or something between the control and the relay. Or is it more complicated than that?

Just as a side note, I can run M26 (Tool Unclamp) and the spindle does unclamp and a relay clicks in the back of the machine. So at least that relay works. Also tried M21 (Magazine Right). The control hangs in exactly the same way as above.

Thanks,

Sage Brush