goldenfab

Cast Iron

- Joined

- May 25, 2016

- Location

- USA Prescott , Arizona

Working with the closest local rigger (90 miles away) to get three VMCs (7k, 11k, and 12k lb) moved into my new shop and I don't have any concrete outside yet. The problem we have is the cushion tire forklift they want to use they said is a no go without concrete. They have a pneumatic tire forklift but it isn't rated for the weight.

I'm in central AZ and we have a fair amount of clay and lots of rock. I cut the grade down around the shop removing a lot of the top soil to level everything and whats left is a bunch of rock mostly fractured/decomposed granite and clay. I have a thin layer of ABC road base down and its been driven on for a few years and as long as its dry its pretty dang hard.

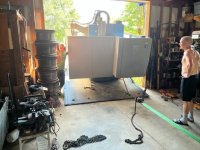

I'm planing on pouring concrete outside but wasn't planing on it until later this year. I've suggested to the rigger we could unload from inside the door and if they can't get their trailer close enough to the door we can put the machine on my goosneck trailer as I know I can get it right in front of my door. The rigger said he's worried about driving the forklift in my driveway unloaded. I offered to sacrifice sheets of OSB and he said that could be problematic too. I have a cat416 backhoe I own on site and it has forks but can only lift about 5k. The only type of forklift avalible to rent around here that isn't 90 miles away I have found is a 12k telehandler and they want $1,750 for the day.

The rigger was confident they would come up with a solution. I think they may have a bigger pneumatic tire forklift but it may require a second semi truck at 180 miles round trip vs the cushion tire forklift which they could use for other work in the area saving costs for both parties.

Here is an areal view of my shop

Here is a planview of the shop

Here is an outside view of the front 12'x14' door of the shop.

Here is a picture of the gravel in front of the door

Besides pouring concrete and waiting 30 days for it to cure is there anything I can offer to make it easier for the riggers and not rent a telehandler for $1,750? The only thing I can think of is adding a layer of material like crusher fines and going over with a plate compactor.

I'm in central AZ and we have a fair amount of clay and lots of rock. I cut the grade down around the shop removing a lot of the top soil to level everything and whats left is a bunch of rock mostly fractured/decomposed granite and clay. I have a thin layer of ABC road base down and its been driven on for a few years and as long as its dry its pretty dang hard.

I'm planing on pouring concrete outside but wasn't planing on it until later this year. I've suggested to the rigger we could unload from inside the door and if they can't get their trailer close enough to the door we can put the machine on my goosneck trailer as I know I can get it right in front of my door. The rigger said he's worried about driving the forklift in my driveway unloaded. I offered to sacrifice sheets of OSB and he said that could be problematic too. I have a cat416 backhoe I own on site and it has forks but can only lift about 5k. The only type of forklift avalible to rent around here that isn't 90 miles away I have found is a 12k telehandler and they want $1,750 for the day.

The rigger was confident they would come up with a solution. I think they may have a bigger pneumatic tire forklift but it may require a second semi truck at 180 miles round trip vs the cushion tire forklift which they could use for other work in the area saving costs for both parties.

Here is an areal view of my shop

Here is a planview of the shop

Here is an outside view of the front 12'x14' door of the shop.

Here is a picture of the gravel in front of the door

Besides pouring concrete and waiting 30 days for it to cure is there anything I can offer to make it easier for the riggers and not rent a telehandler for $1,750? The only thing I can think of is adding a layer of material like crusher fines and going over with a plate compactor.