I have been piecing together a taper attachment for a while now, and I wanted to provide some photos and measurements to those seeking info about it. I see very few differences overall, and looks like only mounting hole spacing would keep you from using one from a different style machine.

Here are the parts I've collected. I don't have two of everything, but at least I can measure the main castings.

Here it looks like the round dial part is a little beefier, but all the critical dimensions are the same. these parts appear to be interchangable between the two main castings.

These parts are identical

Round dial on top

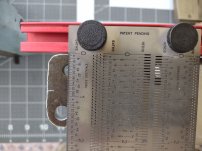

square dial top-row mounting hole distance. Note measurement starts on 1" for every shot with the ruler.

round dial top-row mounting hole distance.

square dial top-row mounting holes are centered on the same plane,

Round dial top-row mounting holes are NOT on the same plane.

Here are the parts I've collected. I don't have two of everything, but at least I can measure the main castings.

Here it looks like the round dial part is a little beefier, but all the critical dimensions are the same. these parts appear to be interchangable between the two main castings.

These parts are identical

Round dial on top

square dial top-row mounting hole distance. Note measurement starts on 1" for every shot with the ruler.

round dial top-row mounting hole distance.

square dial top-row mounting holes are centered on the same plane,

Round dial top-row mounting holes are NOT on the same plane.