Columbia Steel has a wonderful shop. So far, we've only been in building 15, which has about (I didn't go around counting, and haven't even walked both bays of the building) 10 VTLs of various sizes ranging from 6' table "small" ones to at least one 12-14' table monster, 3 or 4 planer mills, and maybe 6 HBMs, plus at least two chunky lathes (guessing 20 or 24" swing, haven't taken a close look.) Bridge cranes and heavy jib cranes almost everywhere, plus aisles large enough for forklifts and work-in-progress. Heavy work tables (many of them round) up to 12' across, with T-slots that would take a 1" or 1-1/4" bolt or recessed shackles for fastening 3/4" or 1" chain.

Guys working there ran down a list of recent projects and most of them were heavy, high impact equipment, like rock crushers, cement mills, parts for drag lines ("steam shovels" bigger than office buildings). Richard mentioned they were building hammer-mill car shredders on his previous visit. A couple of times today, I thought there was a low-flying propeller aircraft buzzing the building. About the third time it happened, I realized that was chatter from a very large part. Whatever it was, was so massive that what would be a high-pitched squeal on a smallish part was a low throbbing vibration on the big part.

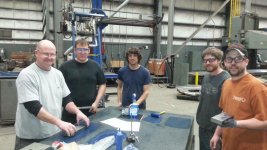

There is also a heat treat oven large enough to take a rail car. I think the door is something like 16' x 12'. The tracks for the car are visible over my shoulder in the 1st pic and in the background in another.

That's just one building. They've got a full foundry and pattern shop and a bunch of other buildings I can't even list. We should get at least a brief, partial tour in the next day or two.

Added in edit: They also have what looked a lot like a railroad wheel press.

But the block you have looks nice...have a great time.

But the block you have looks nice...have a great time.