arsenix

Aluminum

- Joined

- Jul 28, 2011

- Location

- Milpitas, CA

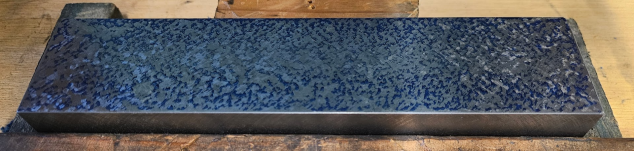

As a first scraping project I bought a Foster 8" straightedge. I did the machining and am now scraping the base of it. I have a Biax BL-10. I'd love some feedback. I did about 15 passes on it and it is looking I think pretty decent but the fine finishing isn't easy (not shocked!).

First pass is after I rough-scraped it (full stroke on the BL10). I dropped the stroke down as the spots got smaller. The last passes were set around 3mm for the last few passes. I can see that some of the high spots are "shinier" than the others and I presume these are the highest areas. Difficult to hit a single spot with the power scraper but maybe i just need to go slower and practice more. Would it be easier to switch to a hand scraper for the final passes? I may also just be going to light now. I notice a lot of my "chicken scratches" are on areas that are still showing high.

My plan is to scrape this in and then use it to spot the compound slides first. They don't have any particular "alignment" with the rest of the lather other than needing to be parallel with their base, so should be straightforward.

First pass is after I rough-scraped it (full stroke on the BL10). I dropped the stroke down as the spots got smaller. The last passes were set around 3mm for the last few passes. I can see that some of the high spots are "shinier" than the others and I presume these are the highest areas. Difficult to hit a single spot with the power scraper but maybe i just need to go slower and practice more. Would it be easier to switch to a hand scraper for the final passes? I may also just be going to light now. I notice a lot of my "chicken scratches" are on areas that are still showing high.

My plan is to scrape this in and then use it to spot the compound slides first. They don't have any particular "alignment" with the rest of the lather other than needing to be parallel with their base, so should be straightforward.

I have everything in house for #1 I just need to put it together.

I have everything in house for #1 I just need to put it together.