tpeters910

Plastic

- Joined

- Dec 14, 2013

- Location

- SE PA

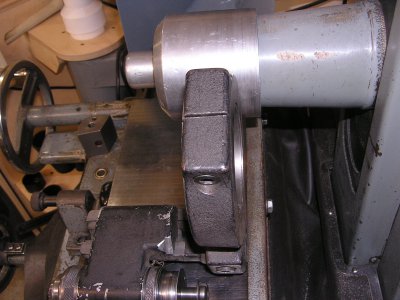

I bought this attachment a couple of weeks ago at an auction in Long Island NY for what I thought was stupid cheap (actually several things, but I digress..). Seems like items close to home go for crazy prices, and most things further away for silly cheap, so thought 'what the heck'. This was worth the 2-1/2 drive alone, but with the others, made the trip well worth it. I have used at least three types of these high speed attachments during my professional tool & die maker career (Boyar Schultz, SpeedLine, and one other), and always wanted one. Very useful for grinding slots, IDs, and other things you can't reach with a 5-7" wheel and the guard. It has 7 spindles, 4 belts, and was less than one spindle for a SpeedLine you see on the bay regularly.

My first issue - It has no name, p/n, model number, or anything on it that I can find. It does have "Leviton" ground into the cover with a high speed steel burr. After some web searching, I think that may have been a previous local company that owned it before the place I got it from. Note that unlike any attachment I have ever seen, this one has a 2nd .5 dia step at the back to drive it even faster than the std 1.5" dia step. The drive pulley that attaches to the grinder fits the std 3"/foot taper, and is 3.800 dia rather than the typical 5" input. I calculate this to run at about 9,000/27,000 rpm, instead of the typical fixed 12,000 rpm of other brands. Bearings are very smooth, so should be good to go.

My real issue - It doesn't seem to fit my Boyar Schultz. The easy to fix problem is that this has a 3.250 bore in the casting mount, with a split sleeve that reduces down to 3.000 dia for most grinders. Boyar Schultz was always a litle odd in that they used 3.125 dia for that guard mount dia, so I have to make a new thin sleeve. No biggie. My real concern is the drive pulley is so long that it completely covers the 3.125 dia attachment collar the casting mount has to clamp to. If I scrap the pulley and make a new 3.800 drive pulley that mounts to a std wheel hub, it seems like once you got the belt on the grinding wheel end of the spindle would always be so far fwd that it is off the front of the chuck, rendering it about useless.

Anybody ever seen one of these, know what make/model it is, and/or know what surface grinder it was designed to fit? Turning out to look like not such a deal. Any suggestions?

The item

Boyar Schultz bare spindle

Where the mounting casting needs to go

Where the pulley ends

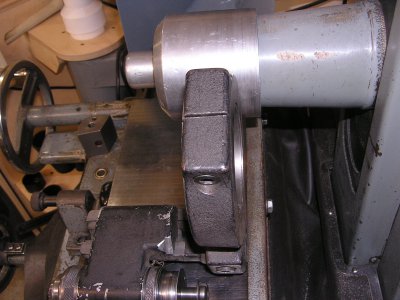

My first issue - It has no name, p/n, model number, or anything on it that I can find. It does have "Leviton" ground into the cover with a high speed steel burr. After some web searching, I think that may have been a previous local company that owned it before the place I got it from. Note that unlike any attachment I have ever seen, this one has a 2nd .5 dia step at the back to drive it even faster than the std 1.5" dia step. The drive pulley that attaches to the grinder fits the std 3"/foot taper, and is 3.800 dia rather than the typical 5" input. I calculate this to run at about 9,000/27,000 rpm, instead of the typical fixed 12,000 rpm of other brands. Bearings are very smooth, so should be good to go.

My real issue - It doesn't seem to fit my Boyar Schultz. The easy to fix problem is that this has a 3.250 bore in the casting mount, with a split sleeve that reduces down to 3.000 dia for most grinders. Boyar Schultz was always a litle odd in that they used 3.125 dia for that guard mount dia, so I have to make a new thin sleeve. No biggie. My real concern is the drive pulley is so long that it completely covers the 3.125 dia attachment collar the casting mount has to clamp to. If I scrap the pulley and make a new 3.800 drive pulley that mounts to a std wheel hub, it seems like once you got the belt on the grinding wheel end of the spindle would always be so far fwd that it is off the front of the chuck, rendering it about useless.

Anybody ever seen one of these, know what make/model it is, and/or know what surface grinder it was designed to fit? Turning out to look like not such a deal. Any suggestions?

The item

Boyar Schultz bare spindle

Where the mounting casting needs to go

Where the pulley ends