A Hardinge DSM-59 followed me home yesterday.

Unloaded it and set it in place.

Time for power.

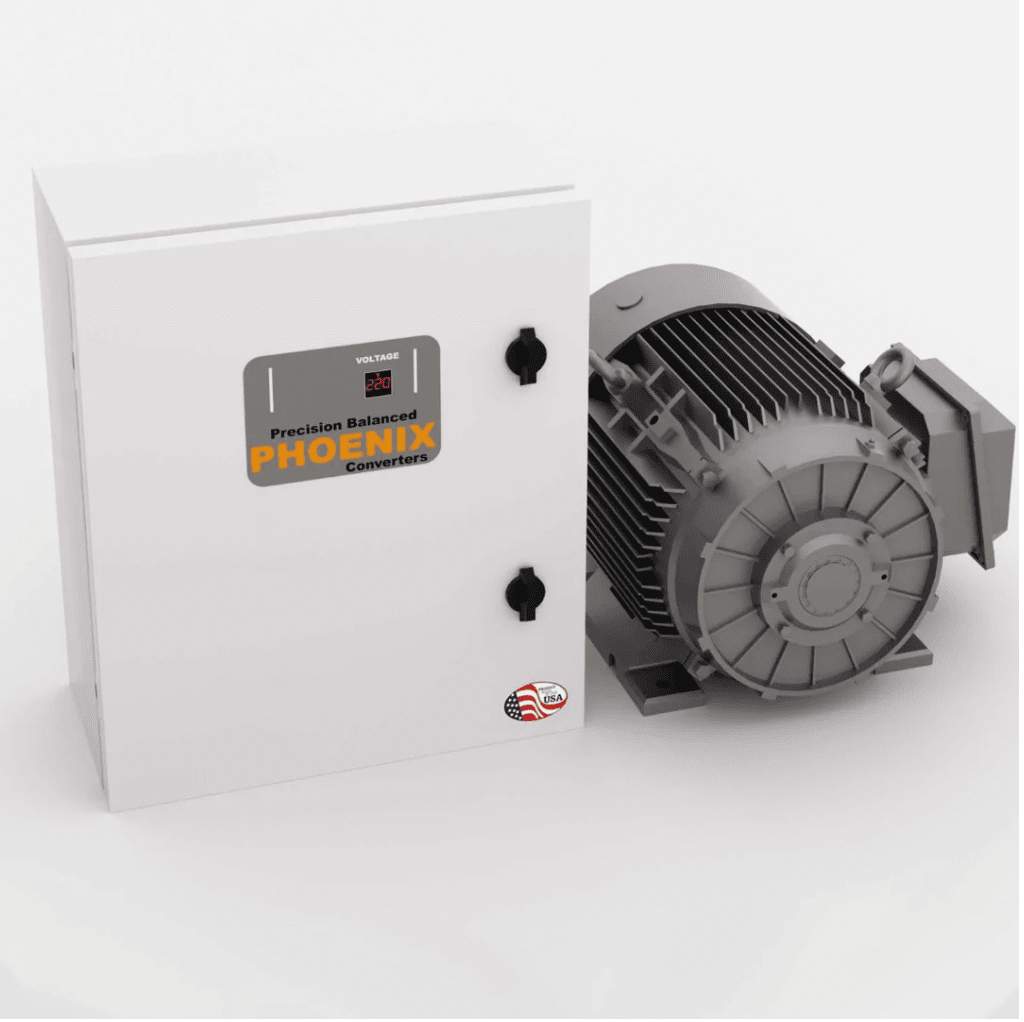

The Hardinge is 220v 3 phase 1 HP, and I have 220v 1 phase power.

I need to acquire a VFD.

Do I just need a drive for 1hp?

The lathe has a power cord connected.

Will connecting to the VFD be a matter of removing the plug, terminating the wires and connecting to the VFD ?

Unloaded it and set it in place.

Time for power.

The Hardinge is 220v 3 phase 1 HP, and I have 220v 1 phase power.

I need to acquire a VFD.

Do I just need a drive for 1hp?

The lathe has a power cord connected.

Will connecting to the VFD be a matter of removing the plug, terminating the wires and connecting to the VFD ?