Josv:

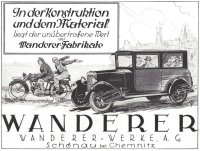

Thank you for your reply. I am enjoying visiting the Wanderer website, and it is quite an interesting history. I had known of the Jawa motorcycles for many years, but never looked into their history. Interesting connection. The Wanderer advertisement you posted is quite a picture in itself. The automobile bears a strong resemblance to a Ford Model A. Having ridden heavy motorcycles (original Triumphs, BMW 'airheads', and Harleys) for over 50 years, I always enjoy learning more about motorcycle history. Of course, the advertisement paints an imaginative picture: anyone who has ridden a motorcycle at any kind of speed knows that the wind (along with road dust and insects) in their eyes is no fun. They also know that the wind will find any opening in clothing or blow thru woven fabrics and chill a rider. Then, we have the lady riding the 'pillion', one hand loosely holding on, one hand waving, all the while riding on a rigid rear frame (no rear suspension) motorcycle. Have to hope the passenger seat ('pillion') is supported on good springs. Advertising artists had quite an imagination and took a lot of 'license' with what they showed.

Your mention of the drive belt still transmitting power in the rain is interesting as well. I was reminded of the history of one of the US machine tool builders, possibly Giddings and Lewis. Their first shop was in rural Wisconsin in the 19th century. The shop also built sawmill machinery, so there were a few buildings with the different departments. One building had the power source (waterwheel or maybe a steam engine) and power was transmitted to the other buildings to drive machinery in them. The means of power transmission was rope drives. Endless hemp rope, long spliced, running over pulleys with multiple grooves. A 'jockey pulley' with a weight maintained tension in the drive rope. The rope drive ran between the buildings, exposed to the weather. Early records of this firm note that work slowed down or stopped in the shops when the exposed rope drives got wet. Slippage of the rope drives occurred and reduce the amount of power the rope drive could transmit.

I was fortunate in that I am old enough to have worked in machine shops which still had some of the original overhead line shafting to drive the machine tools. I went to Brooklyn Technical High School, 1964-68. In those years there were still some of the machine shop classrooms that had not been modernized. These had the 1924 overhead line shafts driving the machine tools. The students nick-named those shop classrooms "belt jungles". Our teacher had come out of industry rather than simply going to a teachers' college. The result was they taught us a lot more than teachers with no real industrial experience could have. We learned how to produce accurate work on old, worn machine tools. We also learned how flat belting worked. Our teachers would sometimes 'walk a belt' up or down the step cone pulleys, hitting the edge of their hand against a moving belt's edge (and pulling away when the lacing hooks came by). We kids were warned not to do this with our hands, but learned to 'walk a belt' using a wrench or hammer handle. I volunteer and do engineering for a working museum in NY State called Hanford Mills. There are lots of line shafts and flat belts in that mill. Whenever I hear the music of the belts and pulleys fanning the air, it takes me back to when I was a kid. I am glad you not only preserved old machine tools, but created an entire old-time shop around them. Please post more about your work and your shop as I am sure many of us here will enjoy learning about it all.