IntegrityMachine

Plastic

- Joined

- Jun 30, 2022

Hello everyone! First post so take it easy on me lol

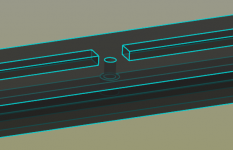

I have a new Haas with a renishaw probe. The goal is to create a cycle to probe two locations in Z, keeping the higher of the two and loading it in G54. I'm trying to prevent gouging the surface near a hole on either side of a key that is being notched out for clearance for a washer and nut. I have already proved out the portion for the XY locations and reprobing for Z next to the hole just a little lost on this one. This is on UHMW and its higher in some places so I have to be careful but really did not want to be stuck at the machine constantly manually probing 500+ times for a part that takes 20 minutes to run with the probing cycle the way it is.

Any suggestions would be great!

I have a new Haas with a renishaw probe. The goal is to create a cycle to probe two locations in Z, keeping the higher of the two and loading it in G54. I'm trying to prevent gouging the surface near a hole on either side of a key that is being notched out for clearance for a washer and nut. I have already proved out the portion for the XY locations and reprobing for Z next to the hole just a little lost on this one. This is on UHMW and its higher in some places so I have to be careful but really did not want to be stuck at the machine constantly manually probing 500+ times for a part that takes 20 minutes to run with the probing cycle the way it is.

Any suggestions would be great!

Last edited: