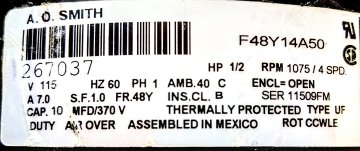

Attached are two pictures of the data plate for an electric motor (F48Y 14A50) I just bought. It says the motor rpm is 1075, but it's also a 4-speed motor depending in the wiring. I cannot find out what the other three speeds are, or, whether the 1075 rpm is the "hi" one or the "lo" one. (I am assuming it's the high one.) Can anyone tell me what the other speeds are, OR, where I can find out what they are?

Of course, I could just run it and tach the shaft, but I'd rather wire it closest to the speed I want first. Plus, why aren't these values just spec'd for goodness' sake?

Thanks in advance,

Paul

Of course, I could just run it and tach the shaft, but I'd rather wire it closest to the speed I want first. Plus, why aren't these values just spec'd for goodness' sake?

Thanks in advance,

Paul