Maybe this is why you don't believe I can hit a tenth or two with a Haas on diameters? I do sweat this stuff and it does make a difference.

Bullshit. A fucking sl3 mori will not do that. You're deceiving yourself. A goddamned landis grinder has to be in real good shape properly operated to do that. Sorry, that's reality.

You are talking bores on a Haas TL-whatever, if I remember right. I have ground bores on a Heald ID grinder. A lot of them, days at a time. The bores ended up as outer races for roller bearings. They had to be one to three tenths on roundness and size.

Had to be, they were bearings. We were reasonably assiduous on temperatures, coolant temps, measuring equipment, quality bore gauges set with ring gauges and so on. Not fanatics, these weren't aircraft turbines but still, pretty careful.

A Heald i.d. grinder is about 10,000 lbs. The table is probably 1,500 lbs. The spindles turn 12,500 or 15,000 depending on the bore size. They have abec 9 bearings, a rebuild was a couple grand back in 1970. The handwheel for incrementing the cross slide had five divisions per tenth ? Or maybe just two ? Anyway, the wheel was at least 12" in diameter, the divisions were 3/16" apart or more ? Sharply engraved and very readable. And the ratchet that fed the wheel took several clicks per division. The bearing area for that table was five feet long ? Hydraulically actuated, very smooth in operation. You'd turn the thing on in the morning, temp-controlled room and let it all cycle for a half hour before you even indicated in the first part, with a 1 1/2" dial alina tenths indicator. The wheel always touched in three places on first contact, where the chuck jaws had held the blank when turning it. Just that chuck pressure caused maybe a thousandth of out-of-round. You'd grind to two thou away then dress. Then grind to one thou away and check the bore. Grind to two tenths away, retract, measure and adjust your infeed setting. Grind to a tenth away and check. Finish grind. There are stops on the table speed handle, so you can kick the speed to the exact same place after a rapid retract and return. Stroke speed changed size. Flood coolant like niagara falls with a twenty gallon reservoir. Seriously, we'd dream of being on the beach in tahiti while the table went back and forth.

Doing all this shit, it was hard work holding one to three tenths on diameter.

This is why I do not believe your haas lathe is "holding tenths".

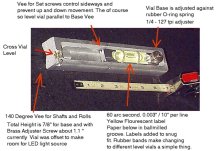

btw, since you mentioned fork tubes - came across this last year, what is this weird thing ? Ha ! Special machine for boring bicycle / motorcycle forks ! Kind of cool. It's not really about "low cost labor" ...

(And since nothing on it is horizontal, they probably don't set it up with a level, ha ha

)

)

)

(too tight) If he'd seen that he'da had more than a few doubts about mistreating that lovely gearbox

(too tight) If he'd seen that he'da had more than a few doubts about mistreating that lovely gearbox