How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cushman 6” three jaw chuck

- Thread starter RRP2024

- Start date

- Replies 15

- Views 574

CWC(4)

Cast Iron

- Joined

- Jan 2, 2017

- Location

- North Central MA

Finding just a replacement pinion the exact size to fit your chuck is probably a long shot. Finding an identical donor chuck might an option but that could be a long journey as well. Otherwise, the welding option might be a viable one.

If you know someone who's good with a TIG torch, you could have the inside sides of the hole built up and regrind to fit with a Fordom or Dremel type tool and carbide burr. Pinions are usually pretty hard and you need to be careful not to soften it with excessive heat. Could be expensive if you brought it to a shop, is the chuck worth it ?

Pictures ?

If you know someone who's good with a TIG torch, you could have the inside sides of the hole built up and regrind to fit with a Fordom or Dremel type tool and carbide burr. Pinions are usually pretty hard and you need to be careful not to soften it with excessive heat. Could be expensive if you brought it to a shop, is the chuck worth it ?

Pictures ?

wheels17

Stainless

- Joined

- May 10, 2012

- Location

- Pittsford, NY

If there is room, I'd suggest that you remove the pinion, bore out the square hole to a convenient diameter for a bushing with a square hole, and fasten the bushing in with Loctite 609 retaining compound.

Thank you for your reply. I have found square hole tubing inserts that would work well for this repair. I have no experience with the Loctite 609 retaining compound. What clearance fit is required for this compound? Another obstacle will be drilling out the square hole. I’m sure this piece is hardened.

For what it's worth I bought a import Sanou 6" 3 jaw with 2 piece jaws several years back & have been nothing but happy with it . I believer several folks here have done the same .

Mine was under $ 200.00 with the backplate when I bought mine . I also had a Cushman 3 jaw that needed help , I'm still workin on that one .

animal

Mine was under $ 200.00 with the backplate when I bought mine . I also had a Cushman 3 jaw that needed help , I'm still workin on that one .

animal

I'd be willing to bet it's not all that hard. A hardened part would crack at the corners, not wear into a round hole.I’m sure this piece is hardened.

Take a file to it and you'll see for sure.

If you are going to bore it, use HSS - carbide won't survive the interrupted cut.

Steve

Great point! I’ll check not out! Thank you! Does anyone have recommendations of clearance needed to use the Loctite 606? I’m thinking about drilling out center and inserting a round tube that has a square 1/4” hole.I'd be willing to bet it's not all that hard. A hardened part would crack at the corners, not wear into a round hole.

Take a file to it and you'll see for sure.

If you are going to bore it, use HSS - carbide won't survive the interrupted cut.

Steve

wheels17

Stainless

- Joined

- May 10, 2012

- Location

- Pittsford, NY

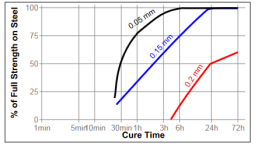

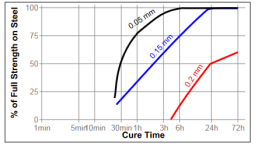

609, not 606. Their main page is https://next.henkel-adhesives.com/u...tral-pdp.html/loctite-609/BP000000153471.html Tech data sheet is https://datasheets.tdx.henkel.com/LOCTITE-609-en_GL.pdf Here's a chart from that document. The tightest clearance is about .002". Ultimate strength is the same even with about .006. Pretty forgiving. Larger gap gives lower ultimate strength. There are also instructions for press fits. Shear strength is listed as 2300 psi

Thank you for your reply and correction. So far I think this is my best option. I’m afraid I may break out into the outside threads when drilling, but I’m going to attempt anyway. The Chuck is at the point where it’s unusable. Here is a picture of the Chuck insert hole in relationship to the outside wall.609, not 606. Their main page is https://next.henkel-adhesives.com/u...tral-pdp.html/loctite-609/BP000000153471.html Tech data sheet is https://datasheets.tdx.henkel.com/LOCTITE-609-en_GL.pdf Here's a chart from that document. The tightest clearance is about .002". Ultimate strength is the same even with about .006. Pretty forgiving. Larger gap gives lower ultimate strength. There are also instructions for press fits. Shear strength is listed as 2300 psi

View attachment 432227

Attachments

dalmatiangirl61

Diamond

- Joined

- Jan 31, 2011

- Location

- BFE Nevada/San Marcos Tx

Does not appear to be enough material left to bore out. I'd either make a key to fit that hole, or just get another chuck. I recently acquired an import YTUM chuck that came with an import dividing head, tore the chuck apart for cleaning and hate to say it, but I was impressed with the machining, how it holds up long term is still to be discovered. They came as a set, so no link to mfr or just chuck, but my guess is just the chuck could not be very expensive. If your existing chuck has integral threads for mounting to spindle, you might need a backing plate to use an import chuck.

Edit: Here you go, they start at $34 , I'm going to assume that is the 80mm size, might need to inquire about pricing on other sizes. https://yantaiytum.en.made-in-china...-Lathe-Chuck-Self-Centering-Scroll-Chuck.html

, I'm going to assume that is the 80mm size, might need to inquire about pricing on other sizes. https://yantaiytum.en.made-in-china...-Lathe-Chuck-Self-Centering-Scroll-Chuck.html

Edit: Here you go, they start at $34

, I'm going to assume that is the 80mm size, might need to inquire about pricing on other sizes. https://yantaiytum.en.made-in-china...-Lathe-Chuck-Self-Centering-Scroll-Chuck.html

, I'm going to assume that is the 80mm size, might need to inquire about pricing on other sizes. https://yantaiytum.en.made-in-china...-Lathe-Chuck-Self-Centering-Scroll-Chuck.html

Last edited:

Dan123

Plastic

- Joined

- Feb 22, 2009

- Location

- Louisville

Flea Bay has a nice one complete with a Southbend backing plate for $100.00.

Similar threads

- Replies

- 0

- Views

- 334

- Replies

- 10

- Views

- 715

- Replies

- 4

- Views

- 419

- Replies

- 10

- Views

- 562