UptownSport

Cast Iron

- Joined

- Jul 25, 2012

- Location

- Cable WI

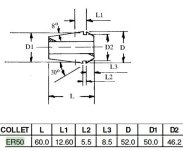

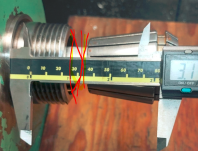

ER collet protrudes from chuck with a considerable length unsupported.

Also,

In drawing rendering AND measurement specified a considerable distance to spindle nose.

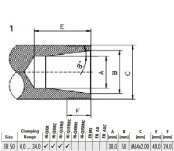

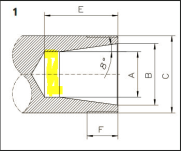

Would the collet compress this much to accommodate it's smallest size?

(There is a small mark on collet at top of caliper at 50mm dia that's obscured by slide)

Is this correct or am I way off on something????

Thanks in advance

Also,

In drawing rendering AND measurement specified a considerable distance to spindle nose.

Would the collet compress this much to accommodate it's smallest size?

(There is a small mark on collet at top of caliper at 50mm dia that's obscured by slide)

Is this correct or am I way off on something????

Thanks in advance