Hi all,

I picked up an industrial press which was part of a automated production process. I not sure how it was plumbed or how fast it moved or anything like that, so I can just try to guess/reverse engineer to the best of my understanding.

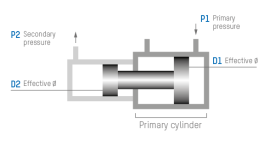

The press cylinder is 8" diameter with a 1" port at the top (rod side), and a 2.5" port at the bottom. Attached to the bottom port is what I believe to be a piston hydraulic accumulator:

There is a 1" line at the base of the assumed accumulator, and a much smaller port (1/2"?) at the top. A point of confusion here - the top port was for hydraulic fluid, not a gas - but in my searching I have not seen any piston accumulators which use hydraulic oil as the "energy storage" side. I'm thinking that it doesn't make sense since it isn't compressible, which leads me to wonder if this is in fact an accumulator.

Questions:

1) Is this an accumulator, and if it isn't, what is it and what purpose does it serve?

2) If it is an accumulator, can I just plug the small port and use it? What purpose could it be used for with oil on both sides? Driving some other part of the circuit, or "accumulator stuff"?

Thank you for any assistance,

Don

I picked up an industrial press which was part of a automated production process. I not sure how it was plumbed or how fast it moved or anything like that, so I can just try to guess/reverse engineer to the best of my understanding.

The press cylinder is 8" diameter with a 1" port at the top (rod side), and a 2.5" port at the bottom. Attached to the bottom port is what I believe to be a piston hydraulic accumulator:

There is a 1" line at the base of the assumed accumulator, and a much smaller port (1/2"?) at the top. A point of confusion here - the top port was for hydraulic fluid, not a gas - but in my searching I have not seen any piston accumulators which use hydraulic oil as the "energy storage" side. I'm thinking that it doesn't make sense since it isn't compressible, which leads me to wonder if this is in fact an accumulator.

Questions:

1) Is this an accumulator, and if it isn't, what is it and what purpose does it serve?

2) If it is an accumulator, can I just plug the small port and use it? What purpose could it be used for with oil on both sides? Driving some other part of the circuit, or "accumulator stuff"?

Thank you for any assistance,

Don