I ask as I have a Feeler 618 (HLV-H copy) that binds up a little when traveling from headstock to tailstock (test with carriage brake dragging slightly) This would indicate some wear, but there is only .0005" difference in the width of the bed overall, as measured from the top of the bed. Suspect I would likely find more than a half thou difference if I was measuring dovetail to dovetail...but how to do that other than making special fixture ? And what about wear in the carriage dovetails ?

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HLV-H .... any experience with measuring the bed ways ?

- Thread starter Milacron

- Start date

- Replies 13

- Views 1,005

AlfaGTA

Diamond

- Joined

- Dec 13, 2002

- Location

- Benicia California USA

Measure across dowels.

Can make a simple test tool by adding a flat plate long enough to cross the bed.

Attach the plate to a gage pin/ dowel ( like a “T”

Run the dowel against the dovetail on one side allowing the plate ( ground or scraped) to ride on top of the bed.

I would relieve the cross plate in the center allowing it to ride on the top of the bed on only the right and left.

Place an indicator /w mag base on top of the plate with the indicator reading on the opposite dovetail face.

Move the gauge along the bed indicator shows change in width as you move.

Flip gage around to read opposite side.

Change reading height of indicator on the dovetail face.

Dowel needs to be of a diameter that it makes contact at 1/3 or 1/2,way down the dovetail face.

I would expect the faces of that bed to read parallel within a tenth or so.

Cheers Ross

Can make a simple test tool by adding a flat plate long enough to cross the bed.

Attach the plate to a gage pin/ dowel ( like a “T”

Run the dowel against the dovetail on one side allowing the plate ( ground or scraped) to ride on top of the bed.

I would relieve the cross plate in the center allowing it to ride on the top of the bed on only the right and left.

Place an indicator /w mag base on top of the plate with the indicator reading on the opposite dovetail face.

Move the gauge along the bed indicator shows change in width as you move.

Flip gage around to read opposite side.

Change reading height of indicator on the dovetail face.

Dowel needs to be of a diameter that it makes contact at 1/3 or 1/2,way down the dovetail face.

I would expect the faces of that bed to read parallel within a tenth or so.

Cheers Ross

Last edited:

Richard King

Diamond

- Joined

- Jul 12, 2005

- Location

- Cottage Grove, MN 55016

If you have a Starrett surface gage with the 2 pins that you can press out. Take them out and mill a L shaped slide that you can drill and tap holes in it that you bolt to the. Bottom of surface gage using the empty holes where the pins were.

You could get a rough idea by mounting a magnet base to the tailstock and reach out with a long rod and indicator. You can also micrometer the flat bed too.

You could get a rough idea by mounting a magnet base to the tailstock and reach out with a long rod and indicator. You can also micrometer the flat bed too.

jccaclimber

Stainless

- Joined

- Nov 22, 2015

- Location

- San Francisco

He's said the bed width is fairly constant. Is it safe to just run the two pins off of that with an indicator point on the dovetail?If you have a Starrett surface gage with the 2 pins that you can press out. Take them out and mill a L shaped slide that you can drill and tap holes in it that you bolt to the. Bottom of surface gage using the empty holes where the pins were.

You could get a rough idea by mounting a magnet base to the tailstock and reach out with a long rod and indicator. You can also micrometer the flat bed too.

Noga arm or similar on the carriage and the indicator on the dovetail portion?

Over dowels would be best, but requires some fixturing.

Richard King

Diamond

- Joined

- Jul 12, 2005

- Location

- Cottage Grove, MN 55016

Hardinge beds are not the conventional dovetail.. look it up. The top is about 8" wide and the front and ___/ <--back side. Not like female dovetails where you can lay dowel pins. Tge cross slide has conventional doves but bot the bed.

jccaclimber

Stainless

- Joined

- Nov 22, 2015

- Location

- San Francisco

Yes, I have one (Sharp in this case). If I were making a drawing for one it would still have distance between dowels. A plate or straight edge on the bed would need to serve as an additional reference for the dowels. Do you know how the factory specified it by chance?

One could also do angle and virtual interaction with the top, but that would be harder to measure with wear.

One could also do angle and virtual interaction with the top, but that would be harder to measure with wear.

triumph406

Diamond

- Joined

- Sep 14, 2008

- Location

- ca

Hardinge beds are not the conventional dovetail..

I have an HLV, HNC and CHNC, all look like conventional dovetails to me.

Peter from Holland

Diamond

- Joined

- Jan 15, 2005

- Location

- The Netherlands

Lift the carriage up and measure how much that is in different locations

The difference gives a decent indication

Peter

The difference gives a decent indication

Peter

Richard King

Diamond

- Joined

- Jul 12, 2005

- Location

- Cottage Grove, MN 55016

Depending on age they came from the factory with a .010" white Nylon applied to the bottom of the saddle. Many times we milled off .025 off the saddle and put Turcite on it. You might call Terry Iverson of Iverson Machine one of the few factory OEM rebuilders left. I've taught 3 scraping classes for them. Tell Terry I Said hello. Oh they call it a bed plate. Good luck. Rich

MCritchley

Stainless

- Joined

- Mar 22, 2007

- Location

- Brooklyn WI

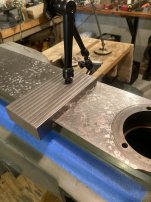

If you’re ambitious you could make up a quick slider. There are two dowel pins that hook under the dovetail. I made this gauge to check my TM column.

The negative about a device as shown is that you would most likely need to pull the carriage to get a good measurement.

The negative about a device as shown is that you would most likely need to pull the carriage to get a good measurement.

Attachments

jccaclimber

Stainless

- Joined

- Nov 22, 2015

- Location

- San Francisco

I’m guessing what he meant, but most machine dovetails have a plane contacting at the narrow end of the male side, so it’s easy to pinch in a dowel. On these the mating plane is the wide end of the dovetail, so holding a dowel is a tad more complicated.I have an HLV, HNC and CHNC, all look like conventional dovetails to me.

Jim S.

Hot Rolled

- Joined

- Sep 4, 2003

- Location

- South Carolina

Seems to me that there is no simple way of doing what Milacron asks (measuring the wear on the dovetail edges). Even a sliding tool, such a MCritchley suggests, only provides partial information. Any tool which references on the top flat of the bedway will necessarily be affected by wear on that top surface, in addition to wear on the bevel surfaces. The problem becomes how to distinguish between wear to the top and to the bevels. Put another way, to accurately measure the distance across the bevels using a tool which references to the top flat, the top flat must be a plane (unworn). That's an unlikely assumption if there is any appreciable wear to the dovetails.

Thought of another way, variation in tightness of the carriage along the length of travel would have to be assumed to a combination of wear to the top of the bed plate and to its bevels.

In the case of my HLV-H, I was able to measure the thickness of the bed plate at the front edge and know with considerable accuracy the wear to the thickness at the front edge. But there is not sufficient clearance to do the same along the back edge of the plate. Once I took the bed plate and was able to measure its thickness throughout, I was surprised at the variation in thickness; both across its width and length.

And, after the bed plate was removed, I made a "sled", ala MCritchley, which referenced off the unworn bottom of the plate and was able to isolate the variation in the width of the plate across the bevels. That enabled me to "map" the plate for variations in both thickness and width.

Jim

Thought of another way, variation in tightness of the carriage along the length of travel would have to be assumed to a combination of wear to the top of the bed plate and to its bevels.

In the case of my HLV-H, I was able to measure the thickness of the bed plate at the front edge and know with considerable accuracy the wear to the thickness at the front edge. But there is not sufficient clearance to do the same along the back edge of the plate. Once I took the bed plate and was able to measure its thickness throughout, I was surprised at the variation in thickness; both across its width and length.

And, after the bed plate was removed, I made a "sled", ala MCritchley, which referenced off the unworn bottom of the plate and was able to isolate the variation in the width of the plate across the bevels. That enabled me to "map" the plate for variations in both thickness and width.

Jim

triumph406

Diamond

- Joined

- Sep 14, 2008

- Location

- ca

I was thinking I measured the width of the dovetail over dowel pins along the length of the bed. And was trying to rack my brain to remember how I did it.

Then I remembered I measured the thickness of the bed along it's length. Up at the chuck end it was -.003 compared to the rest of the bed. At that point I realized there was no point in measuring the dovetail width.

Then I remembered I measured the thickness of the bed along it's length. Up at the chuck end it was -.003 compared to the rest of the bed. At that point I realized there was no point in measuring the dovetail width.

Peter from Holland

Diamond

- Joined

- Jan 15, 2005

- Location

- The Netherlands

What is the purpose of measuring accurate at this moment ????

To me little or non To evaluate a lathe a indication of wear is enough for me

This accurate measurement is of no value before you are going to recondition the ways eighter

Only while you are reconditioning measuring accurate becomes important

Peter

To me little or non To evaluate a lathe a indication of wear is enough for me

This accurate measurement is of no value before you are going to recondition the ways eighter

Only while you are reconditioning measuring accurate becomes important

Peter

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 38

- Views

- 4K

- Replies

- 23

- Views

- 5K

- Replies

- 8

- Views

- 2K