Smouser

Aluminum

- Joined

- Oct 14, 2022

While detailing the refurbishment of my ELLIOT OMNISPEED lathe and explaining how I got a replacement data plate/thread cutting plate, a fellow forum member suggested that I make a thread in the General section of the forum.

This post might help out other members who require a relatively cheap replacement sign or data plate for their machines.

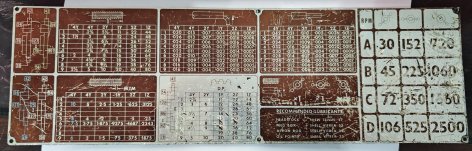

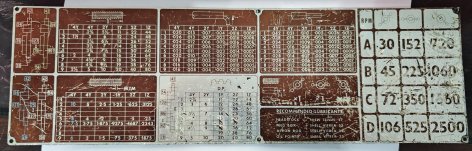

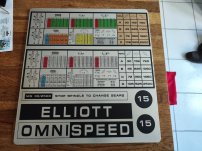

My lathe's information/data plate/thread cutting plate was pretty worn out and damaged.

Luckily, the information could still be read and the lathe's manual also had the required data within it.

I wanted a metal plate to replace the original and tried to recreate the sign on my computer. I soon realised it would take me hours (lack of skill and practice doing this kind of thing).

I remembered that I still had an account at www.freelancer.com and posted the job on there asking for a recreation of the scanned image.

Bids started flowing in instantly (graphics designers must have some algorithm/automatic bid system). I looked through a few bids and selected a Freelancer from Pakistan to recreate the image as he said he could start straight away.

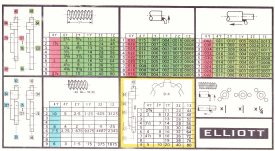

Within a few hours, he sent me the first draft.

As part of the job description on Freelancer.com, I also stated that I wanted the original source file (Adobe Illustrator in this case). Adobe Illustrator uses vector graphics which means you can basically infinitely scale the design without losing quality, unlike an image (jpg, gif etc) which loses quality when you increase its size.

After he made some minor adjustments, I accepted the design, paid the freelancer £20 and he sent all the files over to me.

I then made a few minor adjustments and additions on Adobe Illustrator until I was happy with it.

There are also some free vector graphics design software available.

Affinity Designer and Inkscape but I have not used any of the two and cannot say which one might work better/are easier to learn.

I am in the UK so the following prices and websites apply to the UK only but I am sure similar prices and companies can be found in other countries.

The next problem was, where and on what to get it printed.

I believe the original is on anodized aluminium but I am not too sure. I could not find a place that could provide an instant online quote for anodized aluminium printing but did find a selection of companies that could print on aluminium dibond material.

Lots of companies have a minimum order of £50 - £75 but I found https://www.colour-frog.co.uk which could print the sign for about £21 (375mm x 115mm).

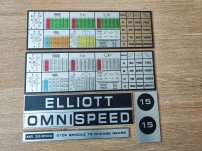

However, for a plate of 375mm x 400mm, it was only £28 so I went for that, that way, I could squeeze two designs of the data plate on and also add some other graphics/plates I wanted.

You have the option of either white dibond aluminium or brushed dibond aluminium.

I chose brushed.

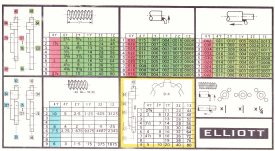

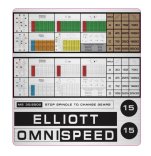

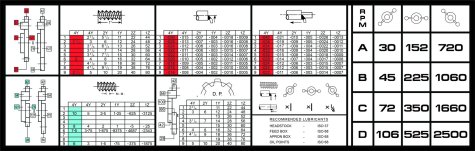

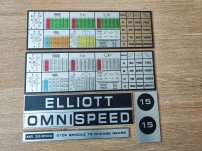

This is the design I sent for printing.

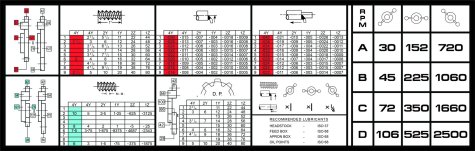

The preview on their website.

The sign arrived a few days later. It was very well packed, wrapped in bubble wrap with corner protection and then wedged in between two pieces of cardboard as outer packaging.

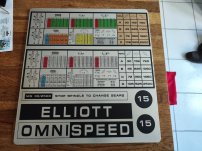

The old sign overlaid on the new.

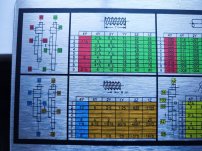

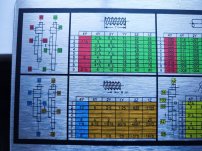

A closeup of the brushed aluminium sign.

Luckily, I had access to a guillotine at work to cut the signs out, it worked perfectly.

While it is not exactly like the original, I am more than happy with my replacement signs.

I hope this helps someone out looking to get some replacement signs made.

My Elliott sign design can be downloaded from here.

It might make it easier to modify/play around with an existing sign before designing your own.

This post might help out other members who require a relatively cheap replacement sign or data plate for their machines.

My lathe's information/data plate/thread cutting plate was pretty worn out and damaged.

Luckily, the information could still be read and the lathe's manual also had the required data within it.

I wanted a metal plate to replace the original and tried to recreate the sign on my computer. I soon realised it would take me hours (lack of skill and practice doing this kind of thing).

I remembered that I still had an account at www.freelancer.com and posted the job on there asking for a recreation of the scanned image.

Bids started flowing in instantly (graphics designers must have some algorithm/automatic bid system). I looked through a few bids and selected a Freelancer from Pakistan to recreate the image as he said he could start straight away.

Within a few hours, he sent me the first draft.

As part of the job description on Freelancer.com, I also stated that I wanted the original source file (Adobe Illustrator in this case). Adobe Illustrator uses vector graphics which means you can basically infinitely scale the design without losing quality, unlike an image (jpg, gif etc) which loses quality when you increase its size.

After he made some minor adjustments, I accepted the design, paid the freelancer £20 and he sent all the files over to me.

I then made a few minor adjustments and additions on Adobe Illustrator until I was happy with it.

There are also some free vector graphics design software available.

Affinity Designer and Inkscape but I have not used any of the two and cannot say which one might work better/are easier to learn.

I am in the UK so the following prices and websites apply to the UK only but I am sure similar prices and companies can be found in other countries.

The next problem was, where and on what to get it printed.

I believe the original is on anodized aluminium but I am not too sure. I could not find a place that could provide an instant online quote for anodized aluminium printing but did find a selection of companies that could print on aluminium dibond material.

Lots of companies have a minimum order of £50 - £75 but I found https://www.colour-frog.co.uk which could print the sign for about £21 (375mm x 115mm).

However, for a plate of 375mm x 400mm, it was only £28 so I went for that, that way, I could squeeze two designs of the data plate on and also add some other graphics/plates I wanted.

You have the option of either white dibond aluminium or brushed dibond aluminium.

I chose brushed.

This is the design I sent for printing.

The preview on their website.

The sign arrived a few days later. It was very well packed, wrapped in bubble wrap with corner protection and then wedged in between two pieces of cardboard as outer packaging.

The old sign overlaid on the new.

A closeup of the brushed aluminium sign.

Luckily, I had access to a guillotine at work to cut the signs out, it worked perfectly.

While it is not exactly like the original, I am more than happy with my replacement signs.

I hope this helps someone out looking to get some replacement signs made.

My Elliott sign design can be downloaded from here.

It might make it easier to modify/play around with an existing sign before designing your own.

Last edited: