How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

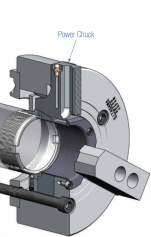

New Power Chuck has a run out, what could be wrong?

- Thread starter 1NoobMachinist1

- Start date

- Replies 30

- Views 1,374

gregormarwick

Diamond

- Joined

- Feb 7, 2007

- Location

- Aberdeen, UK

Toolpost grinder is not even required.I've noticed people are kind of bonky about chucks here but I'd get better than twenty for sure ... put the jaws in the best place and drag out the toolpost grinder, touch 'em up and bob's yer uncle. This crap with "take the part out and turn it around", where did they learn machining ?

Hard jaws are trivial to bore with a CBN insert in a rigid bar. The trickiest part is figuring out how to preload the jaws as the shape of them makes it more difficult that with soft jaws.

I usually use a ring with three pins that locate in the screw holes of the jaws, and just turn the pressure down pretty low.

If the chuck is repeatable regrind the hard jaws. If it's not buy a better quality chuck. Indeed as Greg said use a ring with 3 pins to preload the jaws when regrinding.

Be sure you check the alignment of the machine after such a hard crash. If you don't now how call someone who does.

Be sure you check the alignment of the machine after such a hard crash. If you don't now how call someone who does.

1NoobMachinist1

Plastic

- Joined

- Oct 18, 2023

It's not that I'm not expecting run out I just was not expecting to be able to see it with the naked eye for example here is a video of me machining a 16mm stainless steel rod with hard jaws, if I attempted to do this now with the same hard jaws on the new chuck I'd never be able to to do this as my holes wouldn't be center, my Also here is the link to the youtube video.I've exaggerated of course, but the point was that expecting no runout with hard jaws on a hydraulic chuck is nuts.

1NoobMachinist1

Plastic

- Joined

- Oct 18, 2023

I'm all the way in south Africa, I absolutely do agree that this is above my pay grade I'm actually a civil engineer by profession but somehow found myself in the CNC business. I've been constantly in talks with the supplier and trying to resolve this, hence why I ended up opening an account here, the person that services my machine also insists there is an error with the chuck master jaws.Where are you located. I am sure there is someone near you that can talk you through this, I am not trying to be nasty but this problem seems a little above your pay grade.

???

Titanium

- Joined

- Jun 23, 2017

Where in South Africa.I'm all the way in south Africa, I absolutely do agree that this is above my pay grade I'm actually a civil engineer by profession but somehow found myself in the CNC business. I've been constantly in talks with the supplier and trying to resolve this, hence why I ended up opening an account here, the person that services my machine also insists there is an error with the chuck master jaws.

1NoobMachinist1

Plastic

- Joined

- Oct 18, 2023

Thank you for the input I'm inadvertently learning a lot in this thread with regards to cnc machining.Toolpost grinder is not even required.

Hard jaws are trivial to bore with a CBN insert in a rigid bar. The trickiest part is figuring out how to preload the jaws as the shape of them makes it more difficult that with soft jaws.

I usually use a ring with three pins that locate in the screw holes of the jaws, and just turn the pressure down pretty low.

1NoobMachinist1

Plastic

- Joined

- Oct 18, 2023

I do own a jaw boring ring, I will ask for the service technician to check once more if there is perhaps an underlying problem elsewhere too, on the upside the supplier is bringing a new set of master jaws and new hard jaws to test himself, hoping it all gets resolved by then I'm already down the equivalent of $10k in repairing the machine (chuck and turret replacement), I did clock the internal wedge plunger (measured on the part i marked with blue and the the finger dial gauge gave a total reading of 0.02mm (0.01mm on each side of the zero point line.)If the chuck is repeatable regrind the hard jaws. If it's not buy a better quality chuck. Indeed as Greg said use a ring with 3 pins to preload the jaws when regrinding.

Be sure you check the alignment of the machine after such a hard crash. If you don't now how call someone who does.

Attachments

1NoobMachinist1

Plastic

- Joined

- Oct 18, 2023

the factory is located in brakpanWhere in South Africa.

EmGo

Diamond

- Joined

- Apr 14, 2018

I like grindingToolpost grinder is not even required.

Sure, not required but does a really nice job and not any more difficult than turning with carbide.

Sure, not required but does a really nice job and not any more difficult than turning with carbide. Actually, a lot of my hard top jaws had grippy serrations or prongs. Those you could not true up easily.

Similar threads

- Replies

- 2

- Views

- 132

- Replies

- 3

- Views

- 145

- Replies

- 25

- Views

- 1K