Hi folks,

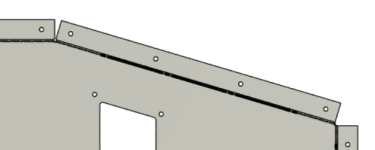

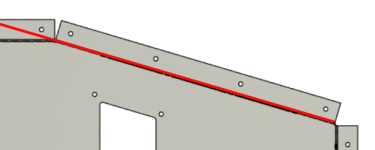

What is the best way to bend the middle flange?

Once that middle one is done, I can do the rest on a 4-foot hand brake. But without bending that first, the bending leaf in the brake also bends part of the next flange. The main issue is in the left where the angle is very wide.

I have 4 of these to do. Two in 0.040" and two in 0.125" aluminum. The flange is 14" x 1". The rest of the part is roughly 4 feet x 3 feet. The bend is on this part for aesthetics, plus there is not enough room in standard 4'x10' sheets to make the flange on the other part this one attaches to. Thanks!

What is the best way to bend the middle flange?

Once that middle one is done, I can do the rest on a 4-foot hand brake. But without bending that first, the bending leaf in the brake also bends part of the next flange. The main issue is in the left where the angle is very wide.

I have 4 of these to do. Two in 0.040" and two in 0.125" aluminum. The flange is 14" x 1". The rest of the part is roughly 4 feet x 3 feet. The bend is on this part for aesthetics, plus there is not enough room in standard 4'x10' sheets to make the flange on the other part this one attaches to. Thanks!