Mr.Chipeater

Aluminum

- Joined

- Apr 20, 2021

I was hoping someone might be able to provide some insight into how I can go about wiring in another pump to turn on/off with an M code.

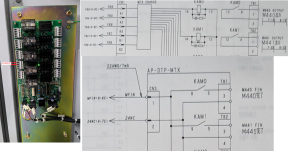

Our machine has the external M code option with the break out board in the electrical cabinet but it looks like all the codes require an MFIN signal to continue otherwise the control just sits on that line in the program.

What does the MFIN need to be and how do I give it one with just an AC pump? Or is there some way around the requirement? I don't see a spare latching M code (like how M08/M09 works).

I called Mori and the guy pretty much said I'd have to call service and have them come out to wire it in which seems silly given we already paid of the external M codes when we bought the machine.

Our machine has the external M code option with the break out board in the electrical cabinet but it looks like all the codes require an MFIN signal to continue otherwise the control just sits on that line in the program.

What does the MFIN need to be and how do I give it one with just an AC pump? Or is there some way around the requirement? I don't see a spare latching M code (like how M08/M09 works).

I called Mori and the guy pretty much said I'd have to call service and have them come out to wire it in which seems silly given we already paid of the external M codes when we bought the machine.