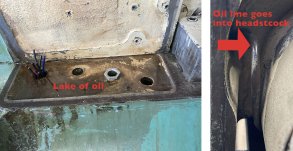

I suspect that you've over-filled the headstock. The line in the second photo is the headstock overflow drain line. If the headstock is over-filled, it drains oil into a depression or oil pan that's cast into the top of the base and includes the area where you found the "lake of oil". There should be a drain hole in the pan, directly under the spindle, that lets the oil drain into the chip pan, but yours has become plugged or painted shut (common). Some models have additional drain ports.

If you take the top cover off of the headstock look carefully in the left rear corner you can find the opening that feeds the overflow drain line. I bet you'll find that the oil level is at or above the opening.

View attachment 428595

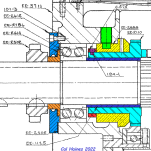

This post shows the drain pan and overflow tube for a round-dial 10EE:

I have been searching here and other locations on the web regarding an oil leak issue I am having on my "new to me" 1942 round dial 10EE. I hope someone may be able to help me. When I add oil to my rear headstock bearing, the sight glass fills to the correct level and within minutes it has...

www.practicalmachinist.com

More information here:

Finally getting close to the end of this rebuild, 2 years into a 6 month resto. As I'm filling various parts of the lathe with oil to chase leaks, I overfill the spindle area and quickly realize the drain line isn't hooked up. Found where I stashed it and couldn't figure out where it is...

www.practicalmachinist.com