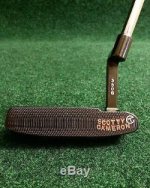

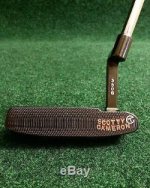

Hello experts. Just wondering about what milling cutter would be best for achieving a deep grooved pattern of milling marks on metal at high feed low rpm. I understand that these marks are a sign of unfinished work, but golfers seem to be desperate to get their hands on putters which faces are milled. I am going to try a fly cutter, but am wondering if had any better suggestions for achieving a pattern like that in the photo attached. Any helpful feedback is appreciated.